How Demand Forecasting Powers the Retail Supply Chain | thouSense

Ever wondered how top-performing retailers in the retail industry stay ahead of market trends and meet customer needs so effectively through demand forecasting? The secret is their expertise in supply chain management, especially through advanced retail demand forecasting tools. These retailers go beyond traditional methods, using cutting-edge technology and data analysis to predict consumer demand with impressive accuracy.

What Is Retail Demand Forecasting?

Demand forecasting in the retail industry involves predicting future customer demand for products or services. It involves analyzing various data sources to make informed decisions about how much stock to purchase, how to price items, and how to manage inventory. Accurate retail demand forecasting is crucial for retailers to ensure they can meet customer needs without overstocking or understocking, both of which can have significant financial implications.

Think of it like planning a big party. If you know how many guests are coming, you can buy the right amount of food and drinks so no one goes hungry and nothing goes to waste. Stores do this to make sure they have what you need when you need it.

Factors Influencing Demand Forecasting and Planning

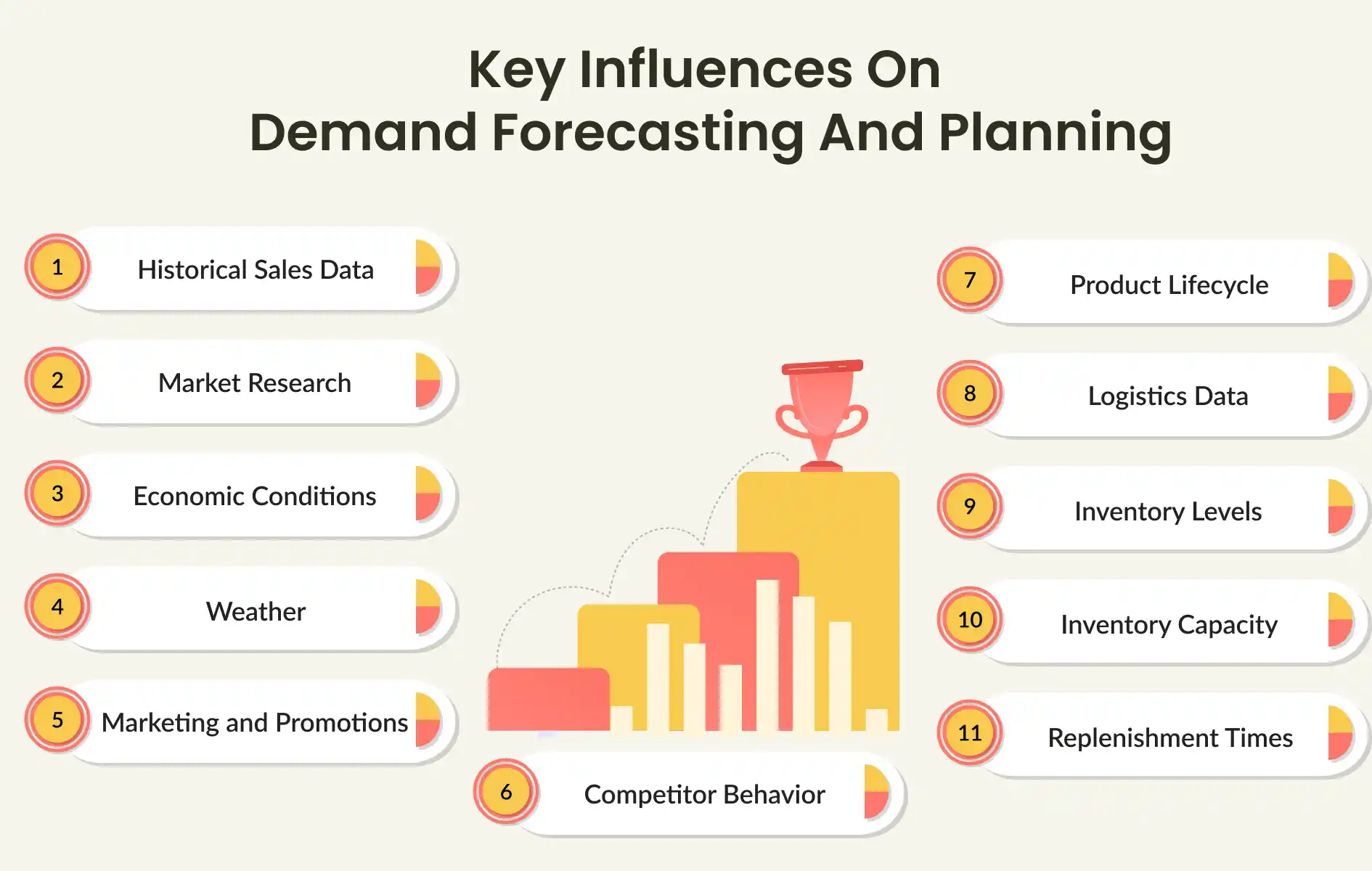

Demand planning in retail, along with demand forecasting in the retail industry, makes precise predictions about future demand by utilizing a variety of data sources. Here are some key data sources and factors that impact retail demand forecasting:

1. Historical Sales Data: In demand planning in retail, examining past sales data is crucial for understanding trends and patterns. By looking at how products have sold in the past, businesses can make educated predictions about future demand. This data shows which products are popular and helps in planning inventory levels.

2. Market Research: Market research provides insights into customer preferences, buying habits, and market trends. By understanding what customers want and how they behave, businesses can enhance demand forecasting in the retail industry. Surveys, focus groups, and market analysis help gather this information.

3. Economic Conditions: Economic factors like recessions, inflation, and interest rates can greatly affect consumer spending. During economic downturns, people might buy less, whereas during boom periods, spending increases. In the retail industry, keeping an eye on economic indicators is essential for effective demand forecasting and planning.

4. Weather: Weather patterns can influence demand, especially for seasonal products. For example, winter clothing and snow removal equipment see higher demand in cold weather. By monitoring weather forecasts, businesses can prepare for changes in demand.

5. Marketing and Promotions: Advertising campaigns, discounts, and promotions can boost sales and change demand patterns. A company that launches a marketing campaign frequently experiences a spike in demand. Planning for these spikes is essential.

6. Competitor Behavior: What competitors do also affect demand. If a competitor launches a new product or changes prices, it can attract customers away. In demand planning in retail, businesses need to stay aware of competitor actions to adjust their own forecasts and strategies.

7. Product Lifecycle: Products go through different stages—introduction, growth, maturity, and decline. In the retail industry, demand forecasting must account for changes at each stage of the product lifecycle. For example, new products might have low initial sales that grow over time, while older products might see decreasing demand.

8. Logistics Data: Information about transportation and shipping costs affects retail demand forecasting. Changes in these costs can influence product pricing and, consequently, demand. Efficient logistics can also ensure timely delivery, impacting customer satisfaction and repeat purchases.

9. Inventory Levels: Having the right amount of stock is crucial. Too little inventory can lead to stockouts and missed sales, while too much can increase storage costs. Maintaining a balance between inventory and demand helps prevent overspending.

10. Inventory Capacity: The amount of space available to store inventory affects how much stock a business can keep. Limited capacity means careful planning to avoid overstocking or stockouts, ensuring products are available when needed.

11. Replenishment Times: The time it takes to restock inventory after it runs out is vital. Longer replenishment times can lead to gaps in availability, resulting in lost sales. Efficient restocking processes help maintain a steady supply and meet customer demand.

By carefully managing these factors, businesses can enhance demand planning in retail, leading to better predictions and the ability to meet customer demand, ensuring they have the right products available while minimizing costs.

Why Is Retail Demand Forecasting Important?

Now, why is this so important? Imagine if your favorite store ran out of your favorite snack just when you wanted it. Or if they had way too much of something and it ended up going bad. Retail demand forecasting helps stores avoid these problems and keep their shelves filled with the right products. Let’s find out how it works its magic in the supply chain.

1. Keeping Shelves Stocked

One of the biggest challenges for stores is keeping their shelves stocked. Retail demand forecasting helps stores predict how much of each product they need, so they can order the right amount from their suppliers. This means you’re less likely to encounter empty shelves when you go shopping.

How It Works

Stores use past sales data to see patterns. For example, if lots of people bought ice cream last summer, they’ll order more ice cream this summer. They also consider special events and holidays, because more people might buy certain things during those times.

2. Reducing Wastage

Retail demand forecasting also helps stores reduce waste. If a store orders too much of something, it might not sell before it goes bad. This is especially important for foods and other items that can spoil.

How It Works

By predicting demand accurately, stores can order just the right amount. This means less products going to waste and more fresh products for you to buy. It’s like knowing exactly how many guests are coming to your party, so you don’t end up with too much leftover food.

3. Saving Money

When stores know what to order and when they can save money, ordering the right amount means stores don’t have to spend extra on storage or worry about unsold products.

How It Works

Stores often get discounts when they order large quantities, but ordering too much can be costly if the products don’t sell. Retail demand forecasting helps them find the right balance, saving money that they can use to offer better prices for customers.

4. Improving Customer Satisfaction

Nothing makes customers happier than finding what they need when they need it. Retail demand forecasting ensures that stores have the products people want, improving customer satisfaction.

How It Works

By studying what customers bought in the past, stores can predict what they’ll want in the future. This means they can keep their shelves stocked with popular items, making customers happy and more likely to return.

5. Helping Plan Promotions

Promotions, like discounts and sales, are a great way for stores to attract customers. Retail demand forecasting helps stores plan these events better.

How It Works

By understanding what products are in high demand, stores can plan promotions around those items. This encourages more people to shop and helps stores sell even more products.

6. Managing Inventory

Inventory management is all about keeping track of products. Retail demand forecasting helps stores know how much inventory they need and when to order more.

How It Works

Stores use retail demand forecasting to create an inventory plan. This plan tells them what to order, when to order, and how much to order. It’s like a grocery list that helps them keep their shelves full without overloading their stockroom.

7. Enhancing Supplier Relationships

Stores rely on suppliers to get the products they need. Retail demand forecasting helps stores build better relationships with their suppliers.

How It Works

When stores can predict demand, they can give suppliers a heads-up about what they’ll need. This helps suppliers prepare and ensures that stores get their products on time. It’s a win-win situation!

8. Adapting to Market Changes

The market is always changing, and stores need to keep up. Retail demand forecasting helps them adapt to these changes and stay competitive.

How It Works

By analyzing trends and patterns, stores can quickly adjust their orders to meet new demands. This means they can stay ahead of the competition and always have the latest and greatest products.

9. Supporting New Product Launches

Introducing a new product can be risky, but retail demand forecasting makes it easier. Stores can predict how well a new product will sell and plan accordingly.

How It Works

Stores look at similar products and customer preferences to predict how a new product will do. This helps them decide how much to order and where to place it in the store.

10. Enhancing Overall Efficiency

Finally, retail demand forecasting makes the whole supply chain more efficient. It helps everyone, from suppliers to store managers, work together smoothly.

How It Works

When everyone knows what to expect, they can plan better and work more efficiently. This means products move from the supplier to the store faster and with fewer hiccups.

Risks of Guesswork in Supply Chain Strategy

Relying on guesswork for your supply chain strategy can be disastrous for retailers. Without using data to make informed decisions, retailers risk making serious mistakes in judging customer demand. These mistakes can lead to either having too much stock or not enough, both of which have negative consequences. Here’s a breakdown:

1. Inventory Mismanagement: When retailers guess at demand, they often end up with either too much stock or not enough. Overstocking ties up money that could be used elsewhere and can lead to wasted products, especially if they expire. Conversely, understocking results in lost revenue and disgruntled customers who can't find what they want.

2. Increased Costs: Incorrect guesses about how much stock is needed can lead to higher costs. Extra storage for excess inventory, wasting perishable goods, and the extra expenses of rushing to restock or offering discounts to clear out excess stock all add up.

3. Supply Chain Disruptions: Without accurate forecasts, the supply chain can become unbalanced. This can cause delays in deliveries, stoppages in production, or overworked distribution channels, all of which disrupt the smooth operation of the supply chain.

4. Customer Dissatisfaction: Poor forecasting means not meeting customer demand, which results in lost trust and loyalty. When customers can’t find the products they want, they may shop elsewhere, hurting long-term sales and damaging the brand’s reputation.

5. Inefficient Resource Allocation: Guesswork leads to resources like labor and transportation being used inefficiently. This increases operational costs and reduces the overall efficiency of the business.

6. Market Opportunity Loss: Retailers may lose out on market possibilities due to inaccurate demand projections. They may not be prepared to take advantage of new trends, losing potential sales to more prepared competitors.

7. Decreased Agility: Without accurate forecasting, it’s hard for businesses to respond quickly to market changes. This reduces their agility and ability to adapt to a fast-changing retail environment.

Exploring the Potential of AI Retail Demand Forecasting

Shifting from traditional forecasting methods to AI-driven insights is a big change in managing retail supply chains. Traditional methods often rely on simple models and human intuition, which are becoming less effective in today’s complex markets. AI retail demand forecasting uses data analytics to provide deeper and more accurate insights. This shift not only improves accuracy but also makes supply chains more flexible and responsive.

Conclusion

Looking ahead, AI will play an even bigger role in supply chain management. AI algorithms are becoming more advanced, and capable of analyzing more complex and diverse data. In order to remain competitive, retailers must stay up to date on current trends.

FAQs

1. When should retailers use demand forecasting?

Retailers should use demand forecasting regularly to plan inventory, manage stock levels, and prepare for market changes, especially during peak seasons and promotional events.

2. Why is retail demand forecasting important?

Retail demand forecasting is important because it helps retailers predict customer demand accurately, reducing the risks of overstocking and understocking, thereby saving costs and improving customer satisfaction.

3. How does retail demand forecasting improve supply chain efficiency?

Retail demand forecasting improves supply chain efficiency by providing accurate data-driven insights, allowing retailers to optimize inventory management, reduce waste, and enhance overall operational efficiency.

4. What is retail demand planning?

Retail demand planning is a method opted by retailers to assess various factors of the market including customer demand. Through the support of retail demand forecasting tools businesses can enhance their supply chain management. It allows retailers to manage their business efficiently with optimized inventories.

5. What is the Importance of demand forecasting in retail industry?

Demand forecasting in retail businesses provides several benefits to the stakeholders. Accurate retail demand planning helps in assessing the brand position and image within one’s consumer base. It also provides an insight into the depths of your business and allows better decision-making with more customer retention.