Accurate Demand Forecasting For Effective Inventory Management

Demand forecasting is becoming more and more crucial in the hectic corporate world of today. It enables businesses to maximize sales opportunities, reduce stockouts, and plan and manage inventory levels efficiently.

Demand forecasting predicts future consumer needs. It uses data and industry trends. This process also considers relevant information. This data establishes the appropriate level of inventory to maintain on hand as well as the timing of replenishment. Reducing waste, boosting customer happiness, and raising profitability all depend on accurate demand forecasting.

Significance of Inventory Management

The Retail Industry Leaders Association conducted a survey revealing that 70% of retailers consider inventory management their top priority. This demonstrates how crucial a role it plays in boosting sales and client happiness. Having the correct items accessible at the right time helps firms avoid stockouts and overstocking by ensuring efficient inventory management.

Demand Forecasting and Inventory Management

Demand forecasting and inventory management go hand in hand because precise demand forecasting enables companies to match their stock levels to anticipated demand. Precise forecasting helps companies prevent overstocking or stockouts—consequences of imprecise forecasting. Financial losses arise from overstocking due to higher holding costs, obsolescence, and markdowns. Conversely, stockouts result in unhappy consumers, lost sales opportunities, and even harm to a brand's reputation.

Businesses may optimize inventory levels, decrease carrying costs, and lower the risk of excess inventory by effectively estimating demand.

An In-depth View of Inventory Forecasting

Inventory forecasting is the process of calculating the inventory needed to fulfill future customer orders based on predicted sales over a specific period. Analyzing historical sales data, planned promotions, and external factors is essential for generating precise sales forecasts.

The Importance of Demand Forecasting

Accurate demand forecasting is essential to effective inventory management because it protects companies from having too much or too little stock. Excessive stock incurs substantial holding costs and risks stock becoming obsolete, whereas insufficient inventory levels result in stockouts, lost sales, and diminished customer satisfaction.

Accurate demand forecasting has several benefits, such as reduced waste and holding expenses, better customer satisfaction, more opportunities for sales, more efficient use of resources, and more profitability.

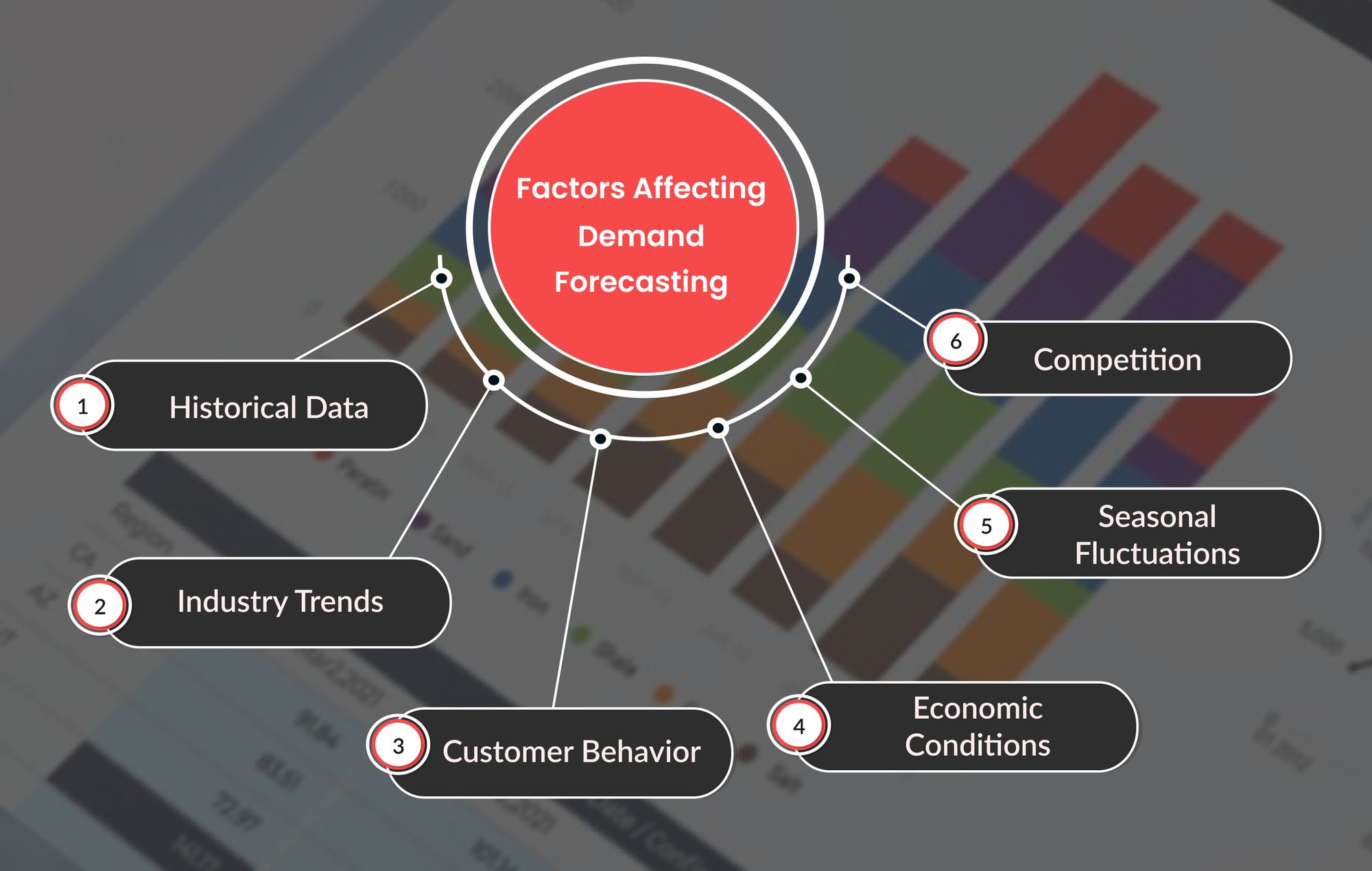

Factors Affecting Demand Forecasting

Several factors influence demand forecasting:

● Historical Data: Examining past sales data provides insights into demand trends.

● Industry Trends: Precise predictions need deep knowledge. This comes from knowing the industry's current state.

● Customer Behavior: Shifts in consumer behavior affect the demand for a product.

● Economic Conditions: Economic factors influence purchasing power and demand.

● Seasonal Fluctuations: Seasonal variations affect demand for certain products.

● Competition: Competitors' actions can influence consumer choices and demand.

Improving Demand Forecasting Accuracy

To enhance accuracy, businesses can employ the following strategies:

● Use Multiple Forecasting Methods: Combining methods like time series analysis, regression analysis, and causal analysis improves accuracy.

● Incorporate Real-Time Data: Integrating real-time sales data into forecasting enables quick responses to changes.

● Consider External Factors: Economic conditions and competition should be factored into forecasts.

● Continuously Monitor and Adjust Forecasts: Regular monitoring and adjustments ensure ongoing accuracy.

What is the Role of Data in Demand Forecasting?

Data is the backbone of accurate demand forecasting. Organizations should gather and analyze data from various sources, including sales, customers, market trends, economic conditions, and competitor actions. Analysis methods like statistical analysis, regression analysis, and machine learning algorithms help identify trends and patterns for accurate forecasts.

How to Integrate Demand Forecasting with Inventory Management?

Several advantages, such as enhanced inventory control, heightened productivity, enhanced decision-making, and elevated profitability are a result of integrating demand forecasting with inventory management. Accurate forecasts of demand enable companies to make well-informed decisions, simplify processes, and sustain ideal stock levels.

Efficient inventory management is crucial for successful supply chain strategies and excellence in customer service. It aligns supply and demand, impacting a business's financial performance, customer satisfaction, and overall operational efficiency.

● Efficient Resource Allocation: Inventory ties up a significant portion of working capital, and effective management prevents unnecessary tie-up of funds in excess stock while meeting customer demands.

● Customer Satisfaction: Timely order fulfillment directly affects customer satisfaction by reducing the risk of stockouts and backorders.

● Cost Control: Balancing holding costs against the cost of stockouts minimizes overall costs, optimizing raw material purchases and reducing storage costs.

● Supply Chain Efficiency: Inventory management impacts internal operations and the entire supply chain. Accurate demand forecasting leads to smoother production scheduling and improved coordination with suppliers and distributors.

● Revenue Optimization: Effective inventory management maximizes sales opportunities, reduces markdowns, and influences a company's revenue stream.

● Risk Mitigation: Strategic inventory management includes risk mitigation strategies to ensure resilience against unforeseen disruptions.

● Environmental Impact: Efficient inventory management contributes to sustainable business practices by minimizing waste and conserving resources.

Role of Demand Forecasting in Achieving Inventory Management Goals

Demand forecasting acts as the compass guiding businesses through the supply and demand dynamics. It estimates future customer demand, providing insights for informed decisions about production, procurement, inventory levels, and overall strategy.

● Strategic Decision-Making: Anticipating customer preferences and market trends allows businesses to align resources effectively

● Inventory Optimization: Accurate forecasting empowers businesses to stock the right quantities, reducing the risk of stockouts or overstocking.

● Production Planning: Manufacturers rely on demand forecasts to plan production schedules, allocate resources, and ensure timely availability of finished goods.

● Supply Chain Efficiency: Demand forecasts improve collaboration with suppliers, distributors, and logistics partners for smoother coordination.

● Cost Management: Aligning production and procurement with accurate demand forecasts enables effective cost management.

● Marketing and Sales Strategies: Demand forecasts provide critical insights for tailoring strategies to capitalize on trends and preferences.

● Risk Mitigation: A robust demand forecasting process helps anticipate and mitigate the impact of external factors, reducing the risk of disruptions.

The Science Behind Demand Forecasting

At the core of effective inventory management lies demand forecasting. This section delves into the methodologies and principles that enable businesses to navigate the currents of market demand, from traditional statistical approaches to cutting-edge machine learning algorithms.

By understanding the nuances of demand forecasting, companies can tailor their inventory strategies and make optimal decisions in the realm of inventory management.

What is AI-Driven Demand Forecasting?

In the era of advanced analytics and artificial intelligence, businesses can elevate their demand forecasting to unprecedented levels. AI-driven demand forecasting leverages big data to anticipate customer preferences, external influences, and unforeseen events that shape demand patterns.

Introducing thouSense: AI in Demand Forecasting

thouSense is a solution designed to empower small and medium businesses with the capabilities of artificial intelligence and machine learning. Developed by experts who have collaborated with industry giants, thouSense helps businesses improve demand forecasts and efficiently manage their supply chain.

Conclusion

In conclusion, the symbiotic relationship between demand forecasting and inventory management is the cornerstone of operational success. Accurate predictions, powered by data and advanced technologies, revolutionize business operations by optimizing inventory levels, reducing costs, and maximizing customer satisfaction. As businesses continue to navigate the complexities of the market, embracing AI-driven demand forecasting becomes a strategic imperative for staying ahead in the competitive landscape.