Inventory Management Challenges In Supply Chain

Inventory management is the backbone of supply chain operations, directly affecting a business’s bottom line and customer satisfaction. Managing inventory is more than just keeping track of products—it involves precise planning, efficient systems, and seamless coordination across multiple channels. But as supply chains grow increasingly complex, businesses encounter a host of challenges that can disrupt operations, inflate costs, and jeopardize customer loyalty.

This blog dives deep into the key challenges businesses face in inventory management within supply chains and explores actionable strategies to overcome these hurdles.

What is Inventory Management and Why Does it Matter?

At its core, inventory management is the process of overseeing the flow of goods from suppliers to warehouses and, ultimately, to the customer. It includes tracking raw materials, components, and finished products. Efficient inventory management is critical for maintaining a balance—ensuring enough stock to meet customer demand without overspending on storage or risking unsold goods.

In the context of supply chain operations, inventory management is more than just a logistics function; it’s a strategic imperative. Poor inventory control can result in overstocking, which ties up capital and increases storage costs, or stockouts, which lead to lost sales and customer dissatisfaction.

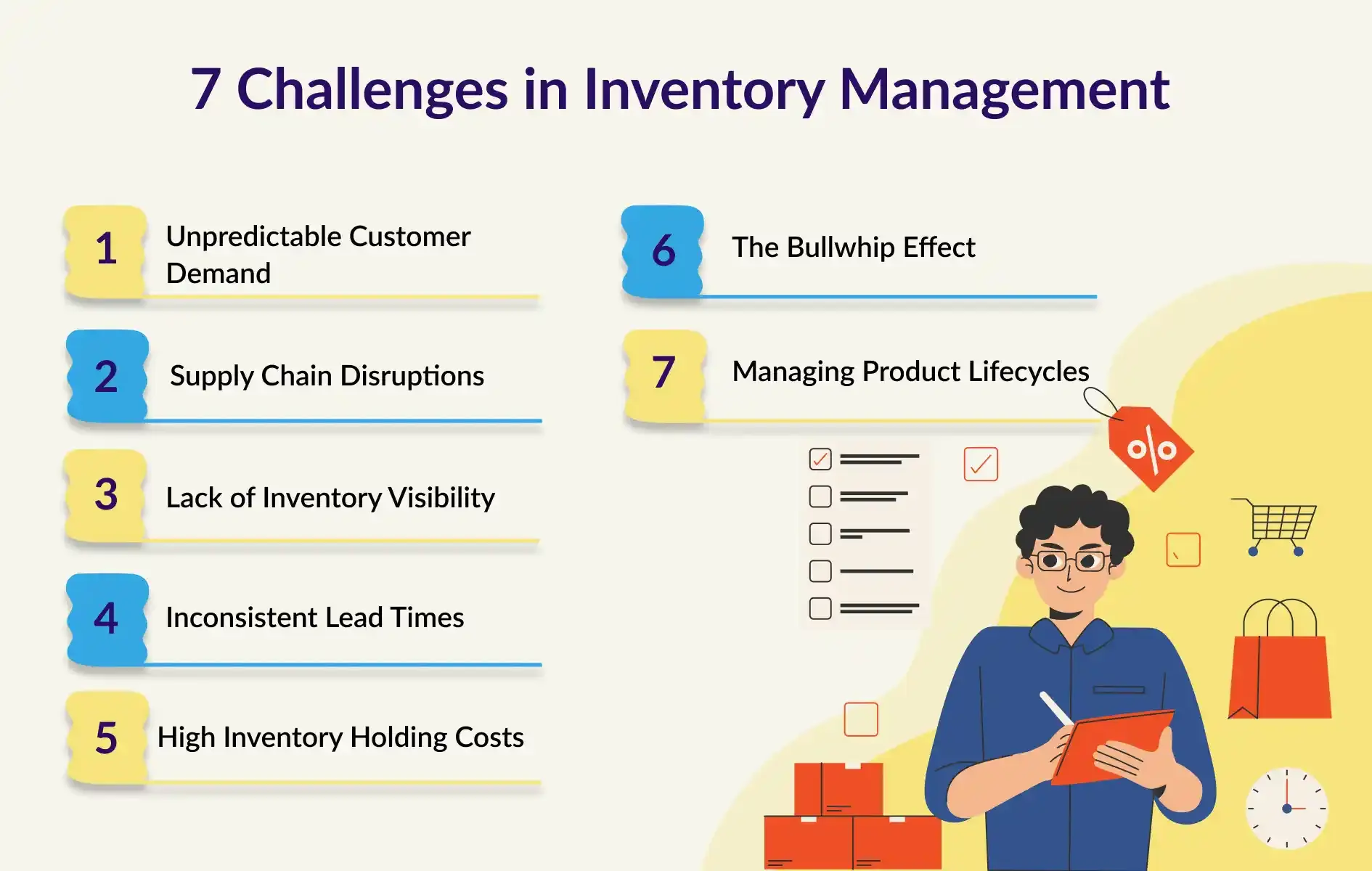

7 Common Challenges in Inventory Management

Businesses often face many problems when handling inventory in their supply chains. Let’s look at some of the most common ones.

1. Unpredictable Customer Demand

One big problem is predicting how much customers will buy. Demand can change because of seasons, the economy, or what people like. If predictions are wrong, businesses may have a problem with overstocking or understocking.

For example, during festive seasons like Christmas or Diwali, demand for certain products such as decorations or sweets can spike, while others might see a dip. Companies that fail to adjust their inventory to these patterns often struggle to meet customer expectations.

2. Supply Chain Disruptions

Sometimes, supply chains get interrupted. These problems can happen because of bad weather, transportation issues, or supplier breakdowns. When this happens, shipments get delayed, and raw materials might not arrive on time.

For instance, a sudden port strike or highway closure can delay shipments, leaving businesses unable to fulfill orders on schedule. Such disruptions make it hard to keep inventory moving smoothly.

3. Lack of Inventory Visibility

Not knowing how much inventory is available is another problem. Businesses need to see their stock clearly at every stage. Without this, they might misplace items, order too much, or fail to deliver to customers.

This is even more important for businesses with many warehouses or online and in-store sales. Real-time data can prevent situations where stock looks available in records but isn’t actually usable.

4. Inconsistent Lead Times

Lead times mean how long it takes for suppliers to deliver orders. These times can change due to production issues, shipping delays, or other problems. If lead times are not steady, businesses may over-order or run out of stock.

For example, electronics companies often face this issue with parts like semiconductors. Long delays can slow down production and cost them money.

5. High Inventory Holding Costs

Keeping inventory costs money. Businesses have to pay for storage, insurance, and other things. If they hold too much stock, especially items that expire or become outdated, it can hurt their finances.

A study showed that these costs can make up 20-30% of a product’s value yearly. Managing these costs is important for profits.

6. The Bullwhip Effect

This happens when small changes in customer demand cause bigger problems in the supply chain. It can lead to too much stock in some places and not enough in others.

For example, if a store sees a small rise in demand, wholesalers might order too much, and manufacturers might make more than needed. This creates confusion and extra costs.

7. Managing Product Lifecycles

Every product has a life cycle with stages like introduction, growth, maturity, and decline. Each stage has its challenges. If businesses order too much of a new product, it may not sell. If they don’t stock enough during its growth phase, they might lose sales.

Technology products, like smartphones, are tricky. A new model can make older ones useless quickly, causing businesses to lose money if they have too much old stock.

Impact of Inventory Management Challenges on Supply Chains

Effective inventory management is crucial for maintaining robust supply chains. Challenges in this area can lead to:

1. Financial Losses and Reduced Profitability

Inefficient inventory practices can result in overstocking or stockouts, both of which negatively impact a company's bottom line. Excess inventory ties up capital and incurs additional holding costs, while stockouts lead to lost sales and potential customer attrition.

2. Decreased Customer Satisfaction and Loyalty

Poor inventory management often results in stockouts, frustrating customers, and diminishing satisfaction and loyalty. Shoppers encountering out-of-stock items may switch stores, purchase substitutes, or abandon purchases altogether, leading to lost sales and a tarnished brand reputation.

3. Ripple Effects on Suppliers and Distributors

These issues also create ripple effects throughout the supply chain. Suppliers and distributors may experience erratic order patterns due to the bullwhip effect, where small demand fluctuations amplify upstream, causing inefficiencies and increased costs.

5 Strategies to Overcome Inventory Management Challenges

Managing inventory well isn’t just about fixing problems—it’s about planning ahead and using smart tools. Let’s look at some easy ways to do this:

1. Advanced Demand Forecasting

Using demand forecasting tools to predict future demand can make a big difference. These tools look at past sales, market trends, weather, and even the economy to guess how much stock you’ll need.

Big companies like Amazon use these tools to figure out what people will want. They adjust their inventory early to avoid running out of stock.

2. Real-Time Inventory Tracking

With modern technology like RFID tags, IoT sensors, and cloud systems, businesses can see their stock levels instantly. This real-time data shows what’s in the warehouse, what’s on the way, and what’s running low. It helps make sure there’s enough stock but not too much.

Walmart, for example, uses these tools to keep shelves full without wasting space on extra stock.

3. Supplier Collaboration

Working closely with suppliers is a smart way to handle problems like late deliveries or supply chain hiccups. Sharing your plans and keeping in touch can help both sides stay ready for changes.

Apple is a great example of this. They work closely with their suppliers so they always have the parts they need, even during global shortages.

4. Just-in-Time Inventory (JIT)

The JIT method means keeping just enough inventory and getting new stock only when needed. This saves money and space. But JIT needs good forecasting and smooth communication with suppliers to avoid running out.

Toyota pioneered the JIT approach, achieving significant cost savings and operational efficiency.

5. Regular Audits and Adjustments

Inventory plans need to be checked often. Reviewing stock levels, reorder times, and supplier performance can help businesses stay flexible. Regular checks also make sure the inventory data is correct.

By doing this, businesses can stay on top of changes and avoid mistakes.

How Technology is Shaping the Future of Inventory Management

Technology plays a pivotal role in overcoming modern inventory challenges. Businesses increasingly rely on tools and systems that automate and optimize inventory management.

● Artificial Intelligence (AI)

AI enables better demand forecasting, identifies patterns, and provides actionable insights to optimize inventory levels.

With thouSense, businesses can harness the full potential of AI to make smarter decisions. Whether it's real-time inventory tracking, predictive analytics, or improving supply chain efficiency, thouSense empowers companies to stay ahead of the curve with cutting-edge technology. Ready to transform your inventory management? Discover how thouSense can revolutionize your operations today!

● Automation

Automation has become a cornerstone of modern inventory management, significantly enhancing operational efficiency. Robotic Process Automation (RPA) excels at streamlining repetitive and time-consuming tasks, such as inventory tracking, stock replenishment, and order processing. By automating these processes, businesses can minimize human errors, reduce operational costs, and improve overall accuracy.

Conclusion

Inventory management is a delicate balancing act. It requires aligning supply with demand while minimizing costs and maintaining customer satisfaction. The challenges are many—demand unpredictability, supply chain disruptions, and rising costs—but they’re not insurmountable.

By taking advantage of the tech that is growing, improving supplier relationships, and adopting smart inventory strategies, businesses can stay ahead of these challenges. In the fast-paced world of supply chain operations, success hinges on how well a company manages its inventory.

FAQs

1. Why is inventory management important in the supply chain?

It ensures products are available to meet customer demand while avoiding overstocking or shortages, which can lead to financial losses.

2. What causes supply chain disruptions?

Disruptions can stem from natural disasters, geopolitical events, pandemics, or supplier issues.

3. What is the bullwhip effect in inventory management?

It’s when small demand fluctuations at the retail level cause large variations upstream in the supply chain, leading to inefficiencies.

4. How can businesses improve demand forecasting?

Using AI, historical data, and external factors like market trends can make forecasting more accurate.

5. What role does technology play in inventory management?

Technologies like IoT and AI enhance visibility, improve accuracy, and streamline processes.