Artificial Intelligence's Place in Demand Forecasting and Inventory Control

Accurate demand forecasting and strict inventory controls are components of supply chain management. They are essential for efficient planning and satisfied consumers. To estimate future requirements, we generally use demand forecasting. We need to analyze past sales data and market trends to cut wastage and prevent stockouts. Inventory control aims to avoid squandering money or space. AI maintains the exact right amount of items on hand to meet demand.

There are precise and adaptive advances in AI. It helps in demand forecasting for inventory control. It has enabled companies to boost operational efficiency and reduce costs. AI is continuing to change supply chain operations. It provides better solutions for inventory management and demand forecasting.

Demand Forecasting and Planning

Precise demand forecasting is necessary to meet customer expectations. It maintains optimal inventory levels. Businesses can use AI-based forecasting tool to analyze historical sales data. They can estimate reliable current market trends and other external factors. These tools scan vast volumes of data for patterns, seasonality, and volatility. It helps to assist firms in increasing their inventory levels.

By managing inventories, businesses may save holding costs and improve customer satisfaction. It lessens excess inventory and stockouts. Also, AI alters the rules of inventory management. It increases customer satisfaction, reduces expenses, and streamlines processes.

Other cases that AI considers are sentiment analysis and rival pricing data. These variables will help to adjust to shifting consumer preferences. AI can adapt to market situations, enabling them to change their inventory strategies.

Types of AI Models Used in Inventory Forecasting

● Time Series Analysis:

1. Finding patterns, trends, and seasonality in pre-collected data. This is the aim of time series analysis.

2. ARIMA models, moving averages, and exponential smoothing are a few methods that used in time series forecasting.

● Machine Learning Models:

1. Machine learning-trained models can learn from data and generate predictions.

2. Uses techniques including linear regression, decision trees, and random forests.

● Deep Learning:

1. Multi-layered neural networks extract features.

2. Includes a variety of CNNs, LSTMs, and RNNs for identifying complex patterns.

● Demand Forecasting Models:

1. Demand forecasting models deal with projecting future demand. Historical sales and market trends serve as the input.

2. This approach combines time series analysis, machine learning, and deep learning.

● Predictive Analytics:

1. Future-focused analytics use machine learning and statistical algorithms to predict possible outcomes.

2. Finds patterns and potential hiccups to aid in improving inventory control.

Five Ways Demand Forecasting Tool Enhances Supply Chain

1. Workflow Automation and Data Consolidation:

Supply chain managers at big companies use many Excel spreadsheets. They do so to manage ERP data. It is usual practice to rely on outdated data when employing this manual method, which can take weeks. Artificial intelligence systems have the potential to integrate with several data sources. They update ERP data without any delay. They also help in daily purchases and manufacturing. AI helps to ensure accuracy and efficiency.

2. Automatic Updating of Ordering Plans:

Artificial intelligence solutions provide prompt answers to common questions. They are about the supply chain, ideal inventory levels, and supply chain disruptions. They offer accuracy and responsiveness by modeling business calendars and modifying ordering plans. This is due to keeping track of supply and demand limits.

3. Managing Supplier Unpredictability:

The increasing volatility of the supply chaincan cause large swings in lead times. It can start with suppliers, throwing off inventory planning. To account for the changes and maintain operational efficiency AI identifies new leads. It automates the ordering plans as well.

4. Forecasting Sales for New Products:

It is very challenging to get historical sales information for new products. Hence, precise demand forecasting is crucial for efficient inventory management. AI software uses demand forecast models for relevant products. They are already available on the market to overcome this issue. It updates these models as new data becomes available. It ensures that forecasts are accurate every time.

5. Minimizing Overstock and Stockouts:

AI solutions give supply chain managers the best purchasing techniques. It helps them to cut overstock and stockouts. They check available data to bring supply and demand back into balance. This proactive approach ensures both client happiness and efficient inventory management.

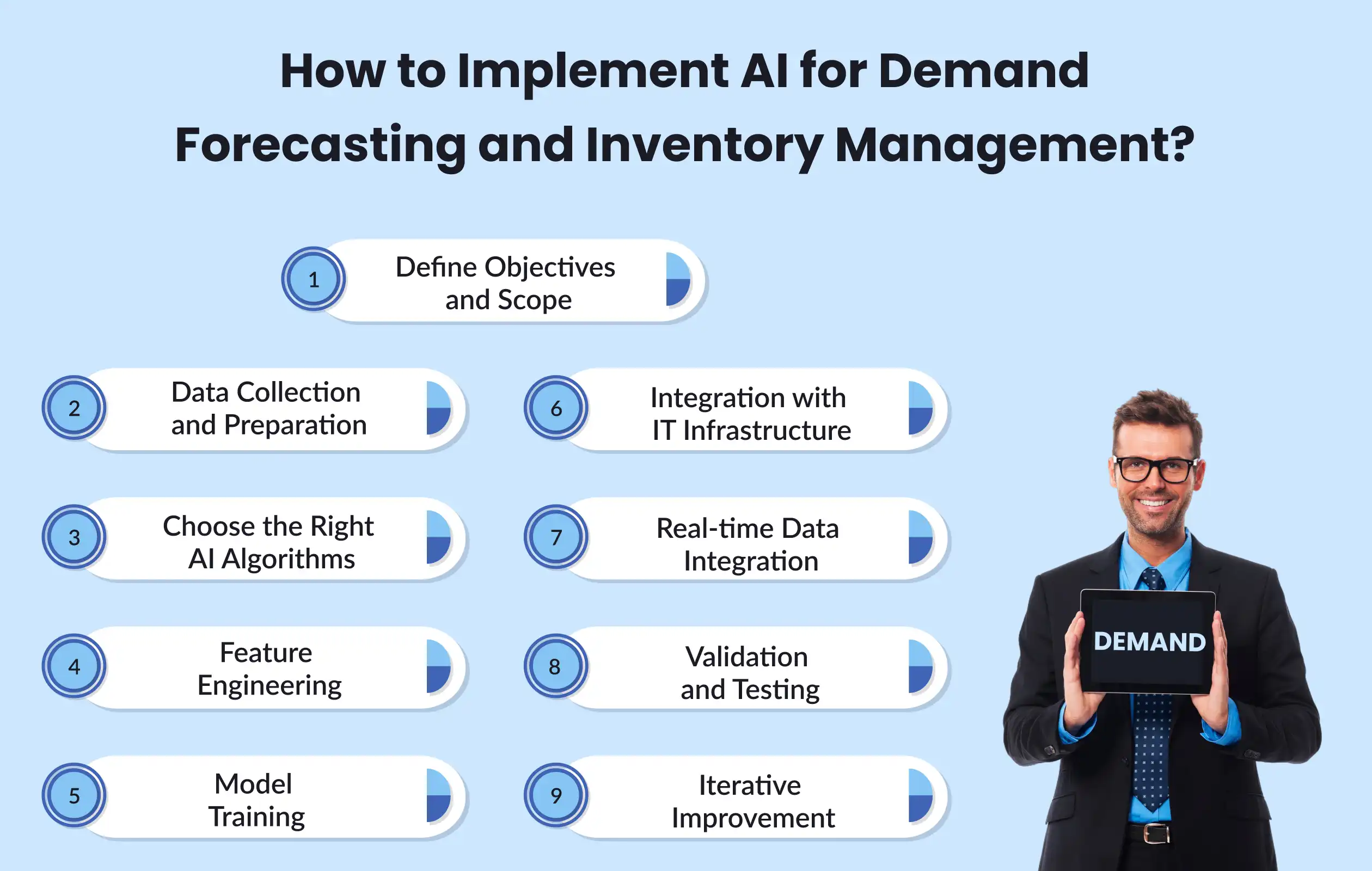

How to Implement AI for Demand Forecasting and Inventory Management?

Demand forecasting for inventory control needs AI in several crucial processes. It ensures precise forecasts and effective inventory management. Let's see how to use AI for supply management and demand forecasting:

1. Define Objectives and Scope:

State your goals for using AI in demand forecasting and inventory management. Find the specific products and services that need AI. Set measurable objectives and create key performance indicators (KPIs) to track progress.

2. Data Collection and Preparation:

Gather historical data on pertinent topics. It includes sales, customer behavior, industry trends, and external impacts. By cleaning and preparing the data, you may ensure that it is reliable and consistent. Address problems with data quality, such as outliers and missing numbers.

3. Choose the Right AI Algorithms:

When choosing AI, check the specifics of the demand forecasting and inventory concerns. Common techniques include decision trees, time series models, and linear regression.

4. Feature Engineering:

Identify practical features that can enhance the performance of the AI models. Integrating or changing current variables helps in forecasting and inventory management.

5. Model Training:

Create two historical sets: a validation set and a training set. You can use the AI to train the model. Check its performance using the validation set. Change the hyperparameters of the model to fine-tune its accuracy.

6. Integration with IT Infrastructure:

Integrate the AI models into the existing IT architecture. Try to get the model up and running on the company's internal or external servers. Take help from data scientists and IT workers who need to collaborate.

7. Real-time Data Integration:

Set up mechanisms to provide real-time data to the AI model. Establish data pipelines or use APIs, to ensure that the model receives the most recent data.

8. Validation and Testing:

Examine the accuracy and effectiveness of the AI model using non-training data. Test the model's resilience by putting it through a variety of scenarios.

9. Iterative Improvement:

Track the AI model's performance and take note of user feedback. Refine the model, taking into account feedback from users and changing market conditions.

Future Trends and Innovations in AI for Demand Forecasting and Inventory Control

AI in inventory management and demand forecasts, is improving supply chain management. Self-governing supply chain systems make things more efficient. AI lets businesses respond to changes in the market. Personalized inventory plans and environmental projects will speed up the process. Explainable AI systems make decision-making more open and trustworthy. It helps businesses adapt to changing markets better.

Optimizing Inventory with thouSense's Forecasting Tool

AI helps to keep up with the fast-paced business world of today. Businesses all over the world are updating their inventory planning management systems. thouSense is there to keep up with customer requests for accurate inventory levels. Adding thouSense to your business can help you find new ways to make money and cut down on costs and waste. Demand forecasting tool increases productivity.

thouSense's AI-driven inventory forecasting features can help with optimizing the supply chain. It also helps in lowering risks and planning for upkeep. This makes sure that the business keeps running and that customers are happy. thouSense is providing the AI tool you need for your business to do well in today's tough market. Even it can solve the hardest problems and can lead to real results.

Conclusion

The use of AI in demand forecasting for inventory control is a big step forward. AI-powered solutions are the best at predicting demand and making operations more efficient. These changes make things easier. They also help companies save money and make customers happier. These solutions help to respond to changes in the market. As AI grows, supply chain management will understand how important it is. It helps to boost innovation, efficiency, and global competitiveness.

FAQs

Ques 1: How do businesses predict what their customers will want to buy?

Businesses look at past sales, consider the time of year, and pay attention to current events to make educated guesses about what will be popular. This helps them have the right amount of products ready for their customers.

Ques 2: What's the trick to managing inventory effectively?

The key is finding the perfect balance—having enough items to meet customer demand without overstocking. This means not too much that it takes up unnecessary space and not too little that it runs out and leaves customers disappointed.

Ques 3: How do modern methods improve forecasting and inventory management?

Modern methods can handle a lot of information quickly and learn from it over time. This means they get better and more accurate at predicting what will sell and how much stock to keep, unlike older methods which might not adjust as quickly to new data.

Ques 4: Can businesses predict if a new product will be a hit?

Yes, they can make educated guesses based on how similar products have sold in the past and what's currently trending. This helps them decide how many of the new items to stock up on, even if they don't have previous sales data for that specific product.

Ques 5: What are the main benefits of using advanced methods for forecasting and inventory?

The biggest benefits include saving time and money, keeping customers happy by having what they want in stock, and staying competitive by quickly adjusting to market changes. This means less wasted stock, more satisfied customers, and a better position in the market.