Revolutionize Business Operations: A Guide to Optimizing Warehouse, Inventory, and Supply Chain Success

In today's highly competitive business world, warehouse optimization is essential. Similarly, improving inventory distribution is not just a choice. It is now a necessity. Managing these areas well can lead to major cost savings. It can also increase customer satisfaction and raise profits. We will offer a basic overview of new operating methods. These methods and business practices can revolutionize your business.

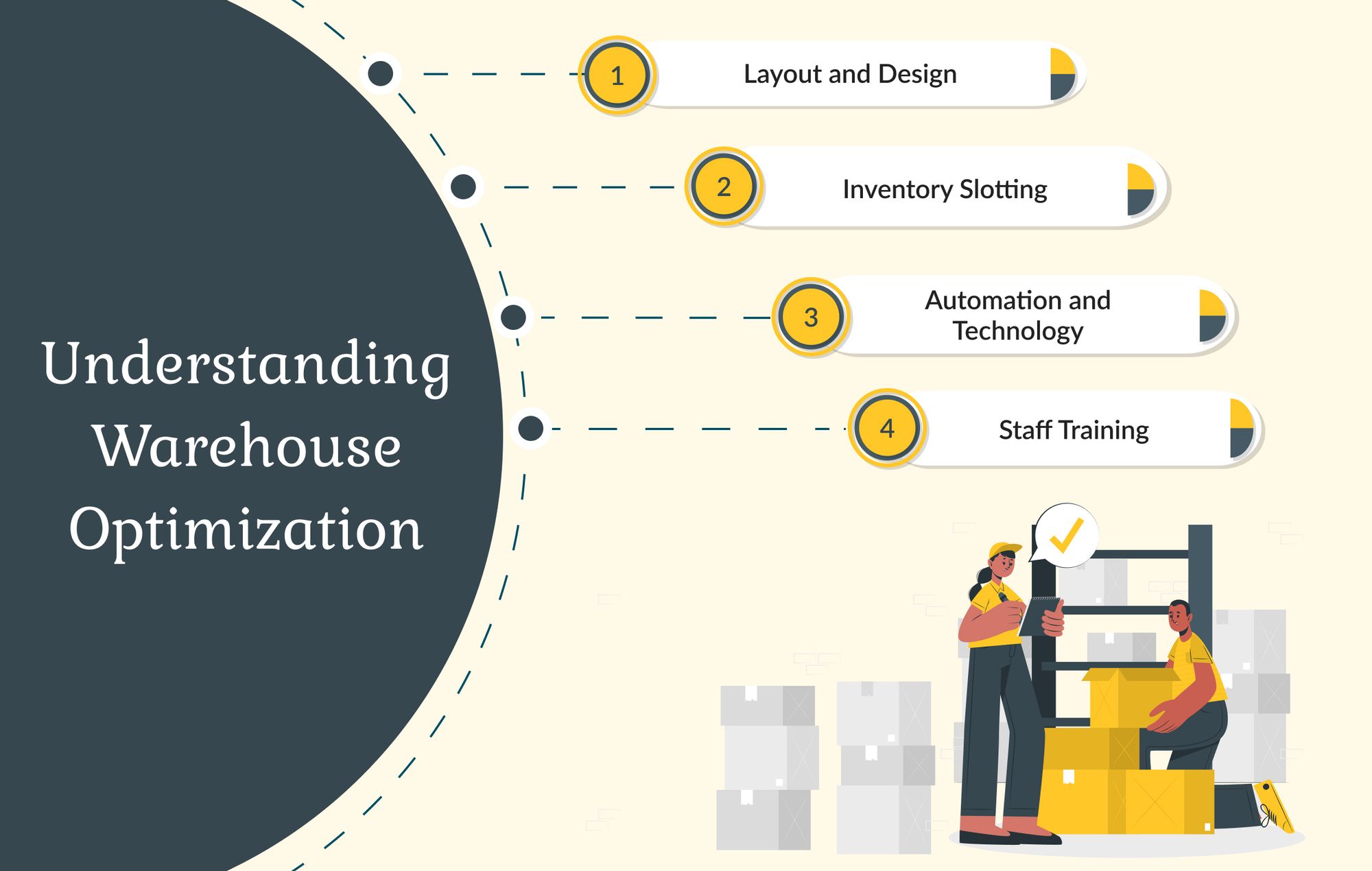

Understanding Warehouse Optimization

Warehouse optimization is the art and science of maximizing operational efficiency within your storage and distribution facility.

1. Layout and Design:

Optimizing the layout and design of your warehouse is fundamental to warehouse optimization. It's about configuring the space to ensure an efficient flow of goods. Efficient warehouse layouts minimize excessive movement, reduce travel time, and optimize storage capacity.

2. Inventory Slotting:

Inventory slotting means placing products in the warehouse in a smart way. You should keep best-selling items easy to reach. This reduces the time workers spend on picking and packing orders.

3. Automation and Technology:

Implementing automation and technologies like RFID and Warehouse Management Systems (WMS) is crucial for effective warehouse optimization. Automation cuts down on manual work. It also makes things more accurate and lets you see your inventory as it is right now.

4. Staff Training:

Well-trained staff are essential. Training ensures employees understand and adhere to optimized processes, reducing errors, and increasing productivity. Training should be ongoing to adapt to changes in technology and processes.

Warehouse optimization is an ongoing process. Constantly adjust your operations to match changes in demand, technology and market conditions. Effective warehouse optimization improves order accuracy, reduces labor costs, and ultimately enhances customer satisfaction.

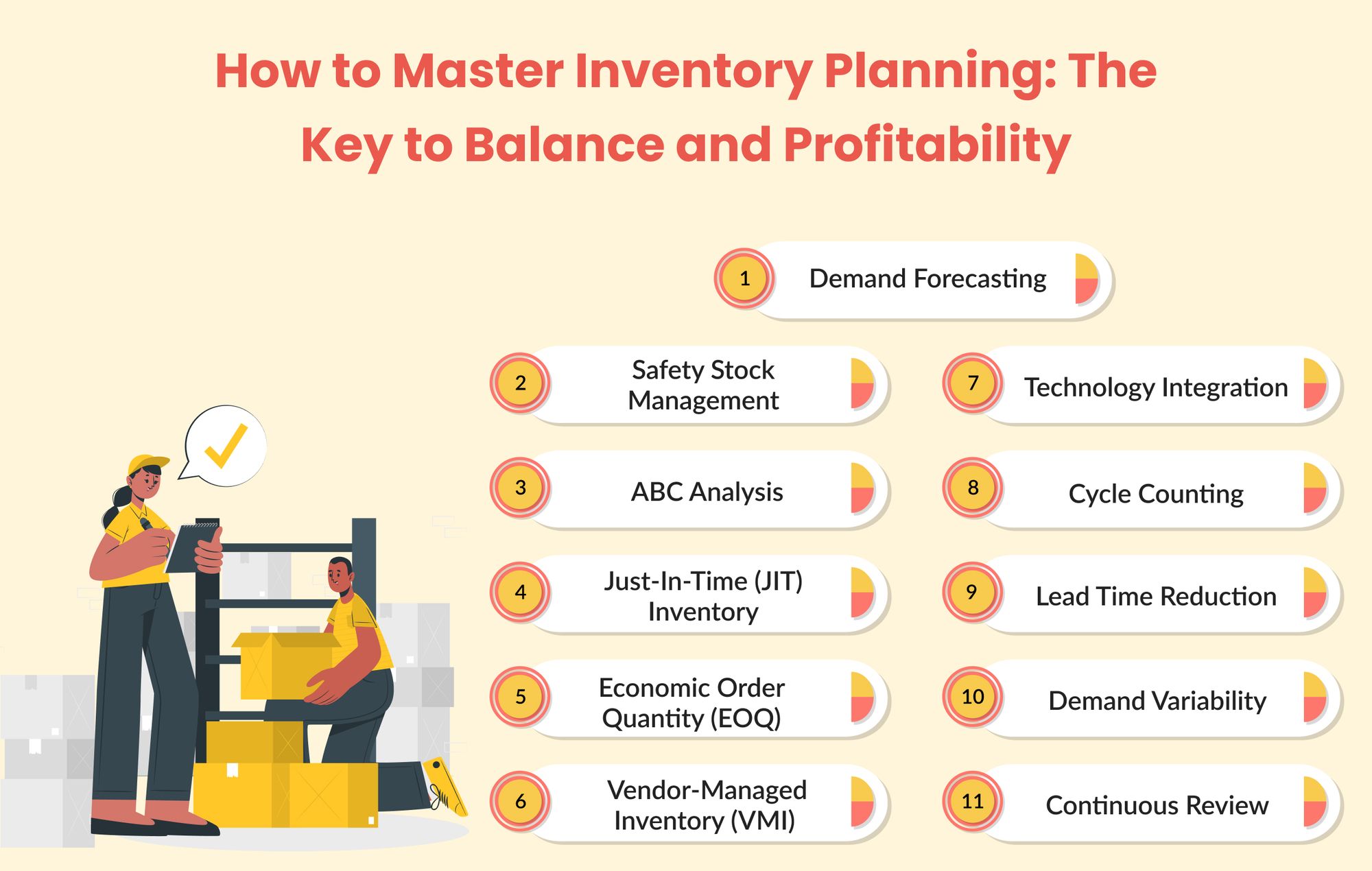

How to Master Inventory Planning: The Key to Balance and Profitability

Efficient inventory planning is the heart of successful supply chain management. It entails precise planning to keep the right products in stock at just the amount customers are likely to demand, maintaining a balance between customer desire and holding costs.

1. Demand Forecasting:

Begin with rigorous demand forecasting. Analyze historical data, market trends, and customer behavior patterns to predict future demand accurately. Utilize statistical models and machine learning algorithms for more precise predictions.

2. Safety Stock Management:

Establish safety stock levels to safeguard against unexpected fluctuations in demand or supply disruptions. Consider factors like lead times, supplier reliability, and market volatility when determining safety stock quantities.

3. ABC Analysis:

Inventory should be divided into groups A, B, and C. Divide them based on their value, how often they are used, and how critical they are. 'A' items are those with high value and are used often. 'B' items have moderate value and usage. 'C' items are either low-cost or moderately useful. Then, distribute your resources and focus based on these categories.

4. Just-In-Time (JIT) Inventory:

Adopt the Just-In-Time (JIT) principles. These principles help cut down on too much inventory and lower storage expenses. JIT focuses on keeping a minimal inventory. It involves ordering and restocking only as necessary. This is to meet customer demand.

5. Economic Order Quantity (EOQ):

First, figure out the Economic Order Quantity (EOQ). This helps find the best order size that lowers total inventory costs. EOQ considers the costs of carrying, ordering, and holding too much inventory.

6. Vendor-Managed Inventory (VMI):

Next, work with your suppliers on Vendor Managed Inventory (VMI). In VMI, suppliers handle your inventory levels. They keep an eye on stock and refill it as needed. This approach cuts your holding costs and ensures on-time deliveries.

7. Technology Integration:

Use advanced inventory management software. This software should connect with your other systems. It should provide real-time updates of your inventory. Order statuses and supplier performance can also be tracked.

8. Cycle Counting:

Implement regular cycle counting to ensure ongoing inventory accuracy. Frequent small-scale counts can identify discrepancies early, reducing the risk of costly errors.

9. Lead Time Reduction:

Aim to shorten lead times from suppliers. Do this through negotiation, better communication, and better transport methods. Shorter lead times mean you can manage your inventory more effectively.

10. Demand Variability:

Understand demand variability for different products. Some items may have steady demand, while others experience seasonal fluctuations. Tailor your inventory strategies accordingly.

11. Continuous Review:

Inventory planning is an ongoing process. Regularly review and adjust your strategies based on changing market conditions, customer preferences, and supplier performance.

Streamlined Supply Chain Management

Effective supply chain management is key to business success. To streamline your supply chain, you need to optimize processes. You also need to improve visibility and get rid of inefficiencies. Let's explore how to create a more streamlined supply chain:

1. Supplier Relationship Management (SRM):

Supplier coordination is crucial in supply chain management. It requires strong relationships with suppliers. Better terms can be negotiated by working closely with them. This ensures cost savings and a steady supply of materials. Open communication with suppliers leads to improved problem-solving, responsiveness, and supply chain stability.

2. Transportation Optimization:

It's also vital to optimize transportation. This is key for controlling costs and ensuring on-time deliveries. Plan and optimize routes and modes of transportation to cut costs and boost delivery efficiency. Choose reliable carriers and reduce empty return trips. This improves supply chain efficiency and sustainability.

3. Inventory Visibility:

Real-time inventory visibility is critical. Monitoring inventory levels, tracking shipments, and receiving instant order status updates allows for quick responses to changes in demand or supply disruptions. This real-time insight prevents stockouts, reduces excess inventory, and ensures products are available when and where they are needed.

4. Risk Management:

Assessing supply chain risks is critical for resilience and continuity. Risks can arise from various areas. These include supplier reliability, geopolitical issues, natural disasters, or market changes. Diversify your supplier base and have backup plans for each production stage. Also, monitor global events that could affect your supply lines.

5. Demand-Supply Alignment:

Matching demand with supply is crucial for good inventory management. Predicting demand accurately and adjusting how much you make and buy helps avoid too much stock. At the same time, it ensures you meet customer needs. This balance keeps the right amount of inventory ready for quick order delivery.

6. Sustainable Supply Chain Practices:

Having a sustainable supply chain is more and more important. Using materials responsibly and having eco-friendly transport matter a lot. They lessen harm to the environment and attract people who care about the planet. Sustainable actions can include cutting down waste, making transport better, and using packaging that's good for the environment.

7. Technology Integration:

Modern software for supply chains is vital for smooth operations. This technology makes important processes automatic. It connects supply chain systems with other parts of your business. It also gives useful information from data analysis. These tech tools provide up-to-date information. They help find areas that are not efficient, bottlenecks, and chances to get better.

8. Collaborative Partnerships:

Foster cooperation among supply chain partners. Sharing data, insights, and best practices enhances coordination and agility. Collaboration extends to joint innovation efforts and cost-reduction initiatives, ensuring a competitive and adaptable supply chain.

9. Lean Principles:

Applying lean principles is key to reducing waste and costs in your supply chain. By identifying and removing activities that don't add value, you streamline your processes. This leads to faster cycle times, lower inventory costs, and better overall performance.

10. Inventory Optimization:

It's essential to maintain optimal inventory levels. It allows cost control and fulfillment of orders. Use demand forecasting, safety stock, and ABC analysis to keep inventory at ideal levels. Proper inventory management ensures that the right products are available when needed, reducing carrying costs.

11. Ethical Supply Chain Practices:

In today's world, ethical practices in the supply chain are increasingly important. This includes responsible sourcing of materials, fair labor practices, and transparency. Adopting ethical practices appeals to socially conscious consumers and meets ethical sourcing standards.

12. Supplier Performance Metrics:

Set clear performance metrics for suppliers and monitor their quality and delivery. Acknowledging and rewarding high-performing suppliers builds stronger relationships. It also ensures a steady supply of quality materials.

Continuous Improvement

1. Kaizen Philosophy:

Kaizen means "change for better." It's about small, data-driven improvements for productivity. Kaizen promotes teamwork, small improvements, setting standards, and valuing everyone's input. This approach leads to ongoing progress and betterment.

2. Lean Principles:

Lean principles focus on getting rid of waste in supply chain activities to achieve the best efficiency. They identify seven kinds of waste. By understanding and removing these wastes, operations become more streamlined. This reduces costs and enhances quality. It fits well with a mindset of constant improvement.

Conclusion

To sum up, revolutionizing your business with better warehouse management, inventory planning, and supply chain strategies is a dedicated process. It demands commitment, careful strategic planning, and flexibility. Implementing the advice, methods, and principles from this guide will greatly enhance your operations. Such improvements lead to cost savings and increased customer satisfaction, which in turn drives sustainable success.

It's important to embrace continuous improvement. This ongoing effort will yield lasting rewards. Staying updated with the new warehouse and supply chain technology developments is a must. Be alert to shifts in the market. Start your path to operational excellence now. Doing so will position your business for growth in a dynamic commercial environment.

FAQ's

1) Why is warehouse optimization important?

Warehouse Optimization helps use space better, speeds up order processing, lowers costs, and keeps inventory accurate. This makes work smoother and keeps customers happy.

2) How can technology help optimize warehouse operations?

Tools like AI, robots, and warehouse software make tasks faster, reduce mistakes, and cut labor costs. Real-time data helps track stock and plan better.

3) What are common warehouse optimization challenges?

Optimization Challenges include messy inventory, wasted space, not enough workers, high costs, and slow orders. Using automation and smart planning can fix these issues.