What Are the 5 Essential Stages of Supply Chain Management?

Supply chain management plays a critical role in ensuring that products move efficiently from production to the end consumer. It involves a series of coordinated processes designed to streamline operations and meet customer demands. In this blog, we will explore the five essential stages of supply chain management and how advanced tools like thouSense can enhance each stage.

Importance of Supply Chain Management

Supply chain management is important for the following reasons:

● Ensures Product Availability: Proper management ensures that products are available where and when customers need them, reducing the chances of stockouts or delays.

● Cost Efficiency: Efficient supply chains minimize costs by optimizing processes, reducing waste, and streamlining logistics.

● Quality Control: It maintains high-quality standards by carefully selecting suppliers and monitoring the manufacturing process.

● Customer Satisfaction: Timely delivery and easy returns lead to happier customers, fostering brand loyalty.

● Competitive Advantage: Companies with well-managed supply chains can respond quickly to market changes, staying ahead of the competition.

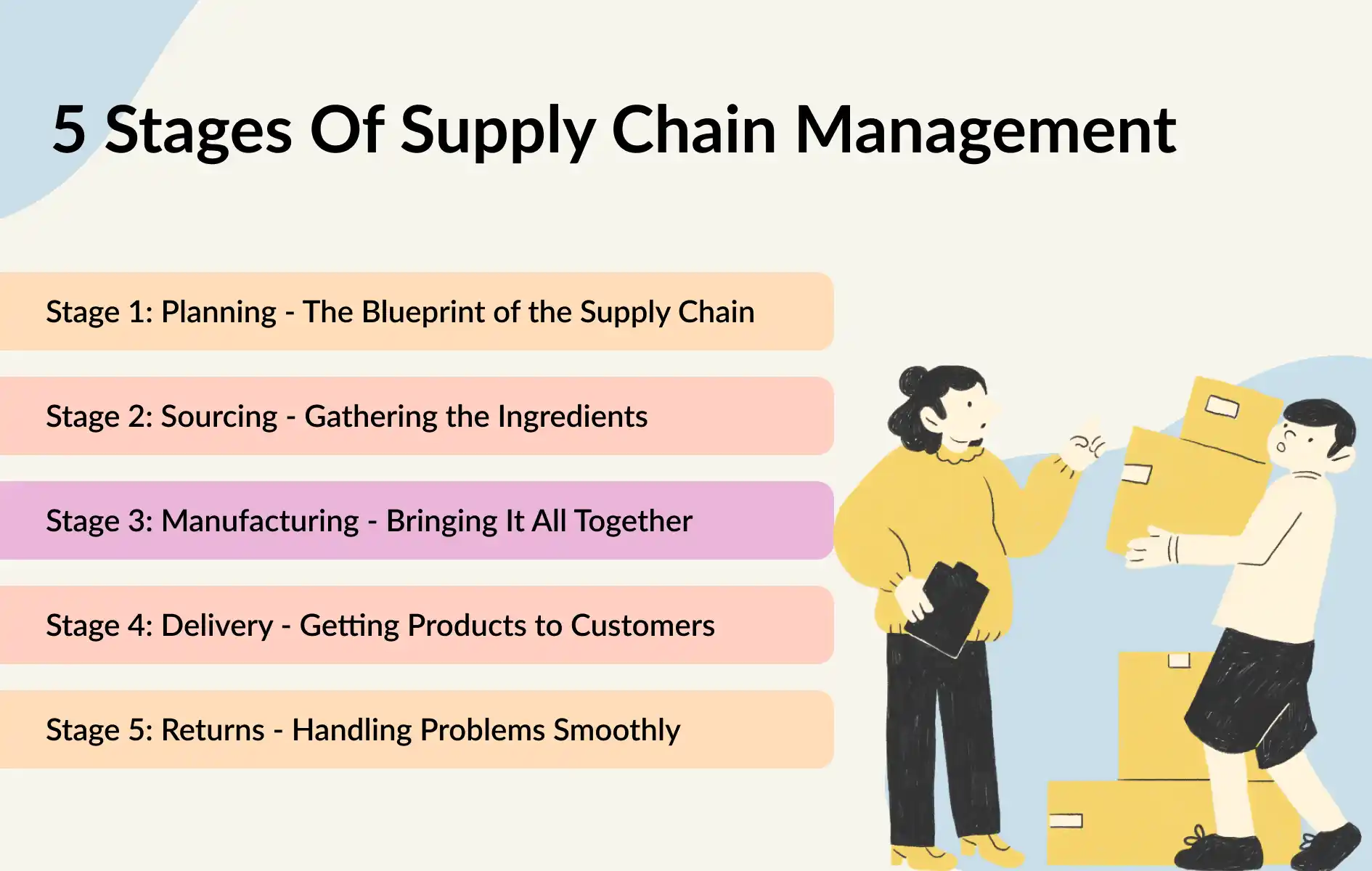

5 Stages of Supply Chain Management

Stage 1: Planning - The Blueprint of the Supply Chain

Planning in supply chain management is about forecasting customer needs and making sure the business is ready to meet them. It involves reviewing past sales data, understanding market trends, and predicting future demand. Accurate planning is essential for a successful supply chain. It helps predict demand, allocate resources, and schedule production. Without proper planning, businesses may produce too much or too little, leading to waste or stock shortages.

thouSense offers advanced demand forecasting tools. These tools use historical data and market trends to make accurate predictions. Businesses can better manage inventory, allocate resources more efficiently, and prepare for demand changes. This proactive approach reduces inefficiencies and keeps the supply chain running smoothly.

Stage 2: Sourcing - Gathering the Ingredients

Sourcing is a critical stage in the production process, where businesses identify, evaluate, and select suppliers that can deliver the raw materials or components needed to manufacture products. This stage requires a careful balance between cost efficiency, quality standards, and timely delivery. Supplier performance and reliability are crucial factors, as even minor delays or inconsistencies in material quality can cause production bottlenecks, increase operational costs, and ultimately affect customer satisfaction.

A successful sourcing strategy goes beyond just price negotiation—it involves establishing long-term partnerships with reliable suppliers who meet or exceed quality and delivery expectations. Regular performance assessments, transparency in communication, and risk management strategies are vital to ensure a steady supply chain.

Stage 3: Manufacturing - Bringing It All Together

Manufacturing is where raw materials are turned into finished products. This stage requires efficiency and accuracy. Any delay or mistake can cause problems throughout the supply chain, leading to missed deadlines or faulty products.

To optimize manufacturing, businesses must streamline workflows, reduce waste, and ensure consistent product quality. Production schedules should meet demand without creating too much inventory, which can raise storage costs.

Stage 4: Delivery - Getting Products to Customers

After products are made, they must be delivered to customers or retailers. This phase, known as logistics, is key to ensuring on-time delivery and customer satisfaction. It involves transportation, warehousing, and distribution.

Efficient logistics require managing different transportation methods, whether by land, sea, or air. Delivery times and costs must be optimized. Businesses must also handle challenges like fuel price changes, regulations, and delays caused by traffic or weather.

Stage 5: Returns - Handling Problems Smoothly

In a well-rounded supply chain, handling returns is just as important as production and delivery. Returns happen for many reasons, like product defects, wrong orders, or customer dissatisfaction. Businesses need to manage returns in a way that keeps customers happy and reduces disruption.

An efficient returns process involves tracking returned products, understanding why they were returned, and providing quick replacements or refunds. This process helps maintain customer trust and gives businesses valuable feedback to improve products and processes.

How thouSense Improves Supply Chain Management

thouSense enhances supply chain management by providing AI-driven insights that streamline operations, reduce inefficiencies, and optimize resource allocation. Through advanced analytics, it enables businesses to predict demand and manage inventory. By leveraging data from various sources, thouSense helps companies make informed decisions, anticipate market trends, and improve supplier relationships. This leads to increased transparency, reduced costs, and more resilient supply chains, ultimately enhancing overall business performance.

Conclusion

Supply chain management is essential for the success of any business operating in today’s complex, global marketplace. The five essential stages—planning, sourcing, manufacturing, delivery, and returns—each play a crucial role in ensuring that products are made, delivered, and returned efficiently. For companies to stay competitive, they must continuously optimize each of these stages.

With advanced tools like thouSense, businesses can leverage data-driven insights to streamline their supply chains, enhance operational efficiency, and build strong relationships with customers and suppliers. In doing so, they not only improve performance but also gain a strategic edge in the market.

FAQs

1. What are the main steps in supply chain management?

The main steps in supply chain management are planning, sourcing, manufacturing, delivery, and returns. These steps ensure that products are made, delivered, and returned efficiently.

2. Why is planning important in supply chain management?

Planning is crucial in supply chain management because it helps companies predict demand, manage resources, and ensure smooth operations. Without proper planning, the supply chain can face delays and inefficiencies.

3. How does technology help in supply chain management?

Technology, like thouSense, helps in supply chain management by providing data-driven insights and optimizing processes. It makes the supply chain more efficient and responsive to changes.

4. What are the 5 phases of supply chain management?

The phases of supply chain management are planning, sourcing, manufacturing, delivery, and returns.