Inventory Optimization Methods: Choosing the Best Approach

A lot of companies use different methods to keep track of their goods. However, they don't always have one fully optimized inventory forecasting solution.

Online retailers may struggle to fulfill customer orders. This is due to the challenge of managing and forecasting inventory levels effectively. Delays in getting raw materials, problems in the supply chain, and changes in demand are hard to predict. This can cause either inadequate inventory, which costs money that isn't needed.

Every online business that wants to be successful needs to understand the idea of product control. Fortunately, using the right inventory optimization tools can make it easier and faster to handle your stock. In this blog, we talk about the basics of inventory forecasting and optimization.

What does Inventory Optimisation mean?

For organizations, maintaining the proper inventory levels is essential. This ensures there's enough stock to meet customer demand without incurring high logistics costs or common problems like stockouts, overstocking, or delayed orders. By finding the right balance, companies can optimize their inventory, keeping costs low while meeting customer needs promptly.

It's an important part of e-commerce that uses new tools, technology, and methods to improve stock management. This makes it possible to keep track of goods in real time, predict demand better, and store things more efficiently.

The Most Important Parts of Improving Inventory Forecasting

To ensure it has the right amount of products for fulfillment, a business needs to look at its storage space. It also needs to keep track of its current inventory and know when its suppliers are due to deliver. It also has to notice seasonal trends and make plans for upcoming sales.

Here is a list of the most important things you need to do to optimize your inventory forecasting:

● Demand Forecasting

Using past sales data to predict how much a product will be wanted in the future is called demand forecasting. By forecasting demand, you can estimate your potential earnings and sales in the coming months. It helps reduce the risk of significantly running out of stock, making customers happier and keeping stock levels at the best level.

● Adding to the Inventory

This means either putting more items on the shelves from what's already there or ordering more from the makers. It's an important step of inventory forecasting to make sure there's enough stock to fill orders right away, which helps avoid backorders and shipping delays.

● Levels of Inventory

Too much inventory can tie up a lot of capital, while not enough merchandise can lead to lost sales and unhappy customers. Finding the best balance by having the right amount of each product lowers the risks that come with efficient inventory forecasting. This makes operations run more smoothly and builds customer trust.

● Storage for Inventory

It is important for businesses that sell physical things to find the best ways and places to store their inventory. Not only does a good storage option meet customer needs, it also helps the business grow cost-effectively. The inventory forecasting approach will be different depending on things like the number of sales, the details of the product, and the distribution needs.

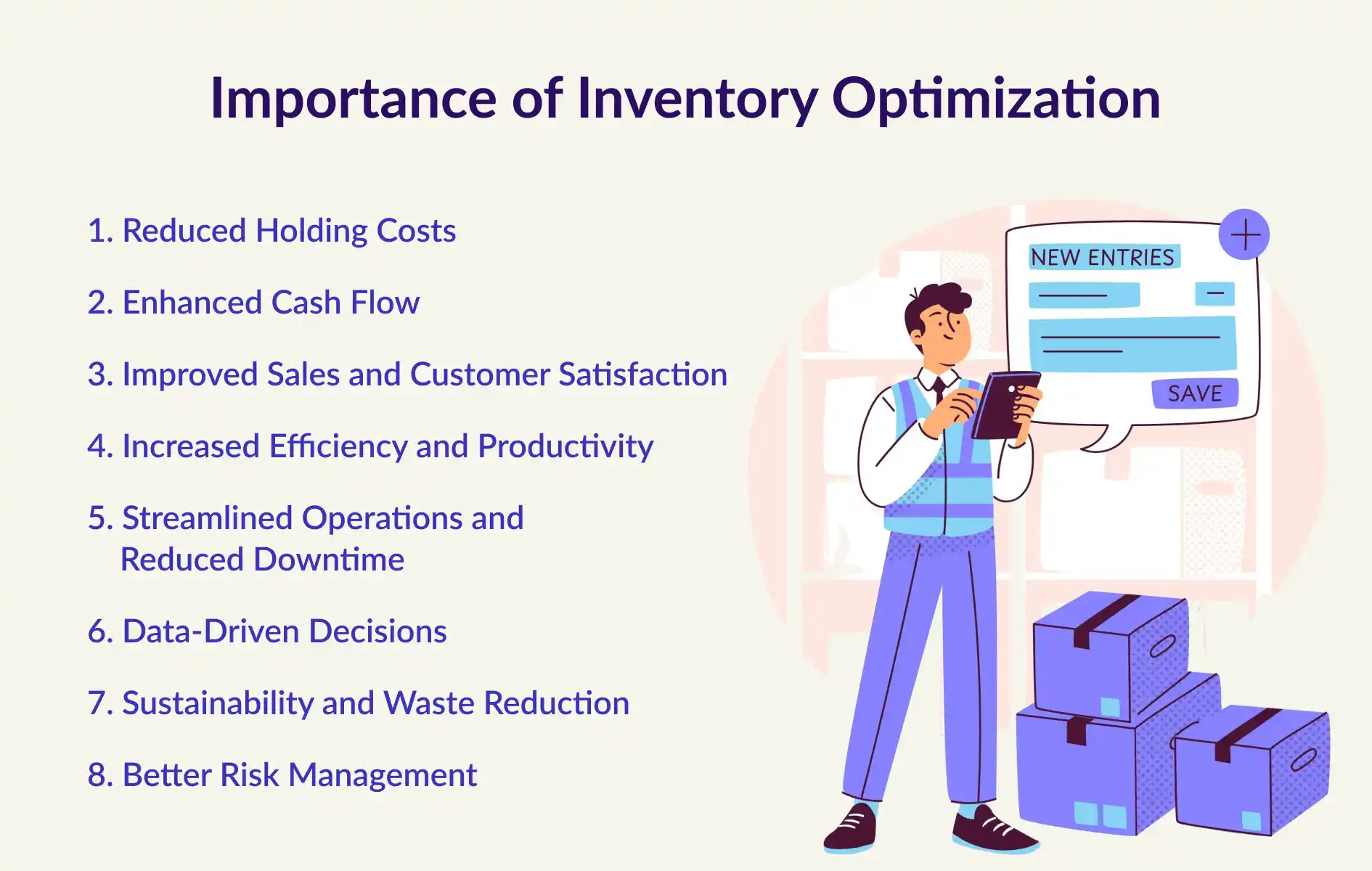

Why Inventory Optimization is Important?

The difficulty of multichannel shopping and unplanned problems like natural disasters and problems in the supply chain make inventory forecasting even more important.

Businesses can plan for the unknown, keep up with demand, and keep logistics costs low by using the right inventory optimization tools and methods. Here are five reasons that make it more important:

1. Reduced Holding Costs

One of the foremost reasons for optimizing inventory is to minimize the holding costs. Inventory that sits in a warehouse incurs costs which include warehousing fees, insurance, and losses due to obsolescence.

● Decreased space requirements: Efficient inventory management reduces space wastage which directly lowers the cost of storage.

● Lower risk of obsolescence and spoilage: Optimization ensures that you're not holding onto products longer than you need to, decreasing the risk of items becoming obsolete or reaching their expiry date unused.

2. Enhanced Cash Flow

Optimized inventory directly influences the liquidity of a business. By maintaining a balanced stock, companies can prevent capital from being unnecessarily tied up in excess inventory. This freed-up capital can then be used for other crucial business operations, such as expansion, R&D, and marketing.

3. Improved Sales and Customer Satisfaction

Having the right stock at the right time plays a critical role in customer satisfaction. Inventory optimization ensures that popular products are adequately stocked and available to meet customer demand.

● Quick fulfillment of orders: Immediate availability of products leads to faster delivery times, enhancing customer satisfaction and loyalty.

● Adaptive to market trends: Being equipped to quickly adapt to changing consumer preferences or seasonal demands keeps businesses competitive and relevant.

4. Increased Efficiency and Productivity

Effective inventory management also improves overall operational efficiency. Automation of inventory processes can reduce manual labor and minimize errors, allowing staff to focus on other critical areas of business.

● Use of inventory management software: Technologies like AI and data analytics can forecast demand more accurately, ensuring that inventory levels are kept optimal.

● Improved vendor relations and supply chain responsiveness: With better inventory practices, businesses can also improve collaborations with suppliers and other partners.

5. Streamlined Operations and Reduced Downtime

In manufacturing sectors, the lack of necessary components can lead to downtime. By maintaining an optimized inventory, businesses can ensure a steady supply of required materials, thereby maintaining continuous production lines without interruptions.

6. Data-Driven Decisions

Optimized inventory helps in collecting precise data on inventory trends and customer preferences. This data is invaluable as it helps in making informed decisions regarding stock management, promotional strategies, and customer engagement.

7. Sustainability and Waste Reduction

As businesses globalize, the focus on sustainability intensifies. Proper inventory optimization can lead to significant reductions in environmental impact through decreased waste, reduced overproduction, and lowering the carbon footprint associated with extensive storage facilities.

8. Better Risk Management

Inventory optimization allows businesses to better predict and manage risks associated with overstocks and stockouts. It helps in aligning inventory levels with predictive analytics and market trends, thereby mitigating financial risks.

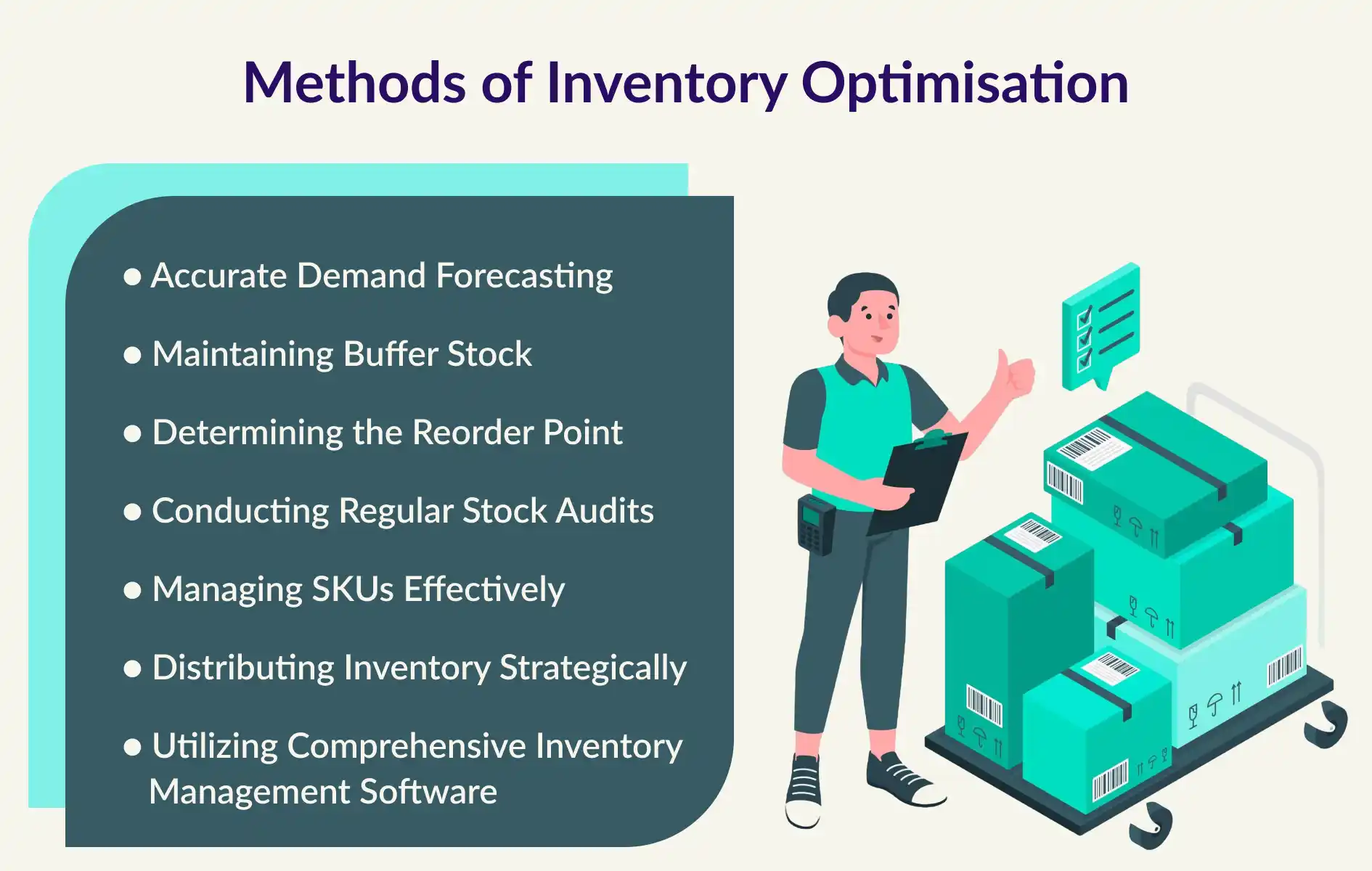

Various Methods of Inventory Optimisation

No matter what size business it is, it needs to use a variety of strategies and best practices to keep track of its goods and make sure that everything runs smoothly in a supply chain. The parts that follow talk about several ways to improve inventory forecasting.

● Accurate Demand Forecasting

Using the right technologies and inventory optimization tools to correctly predict future sales and income is the foundation of smart supply planning. Accessing information about past orders is important for figuring out how sales trends work, which helps businesses improve customer satisfaction, cut costs, and make their supply chains work better.

Inventory forecasting lets you take smart steps like running limited-time sales, hiring more people, or making storage spaces bigger. thouSense and other advanced solutions offer analytics and distribution measures that track how well products are doing over time, which makes planning for the future easier.

● Maintaining Buffer Stock

Having a buffer or safety stock is important in case of unexpected problems with suppliers or sudden jumps in demand. This extra stock makes it easier to handle emergencies or problems in the supply line.

Businesses need to know their maximum and average daily consumption, as well as their lead and shipping times, to figure out the exact amount of safety stock they need. Inventory forecasting is made easier by platforms like thouSense AI that help businesses figure out the best reorder amounts and keep an eye on stock levels.

● Determining the Reorder Point

Figuring out the best time to restock is important to avoid having too many goods and to keep capital from being tied down for no reason. The reorder point formula, which is the sum of the demand during the lead time and the safety stock, helps keep inventory at the right amount.

Even though the idea is simple, keeping track of when to reorder different items can be hard. Using a third-party logistics service (3PL) can make this job easier by setting automatic reorder points and giving daily stock data insights.

● Conducting Regular Stock Audits

For accurate inventory forecasting, it's important to do regular inventory checks and follow the right warehouse receiving procedures. To make sure data is correct, it's important to keep an eye on holding costs, which include hiring, storage, shrinkage, and depreciation.

Today's options make it easy and quick to keep track of inventory by connecting online stores to inventory management software or using a third-party logistics (3PL) company's software for fulfillment.

● Managing SKUs Effectively

To avoid overselling or running out of stock too soon, it is important to keep track of stock-keeping units (SKUs) across all of your sales platforms and distribution networks.

Working with a 3PL makes it easier to get rid of duplicate SKUs and keep track of goods across networks. Their inventory forecasting technology lets companies see their real-time inventory levels, set reorder points, bundle SKUs for sales events, and handle kitting and putting together products.

● Distributing Inventory Strategically

Moving your goods closer to your customers cuts down on shipping costs and delivery times. Using a 3PL that handles multiple fulfillment centers, like thouSense, lets you intelligently distribute SKUs based on what you've learned from past order data.

By having stock in multiple places, this method not only speeds up delivery times and saves money on shipping, but it also gives you a unified inventory forecasting system.

● Utilizing Comprehensive Inventory Management Software

To keep SKUs and orders in sync, you need to use full inventory management software. They give you a full picture of your inventory, fulfillment centers, sales platforms, and interactions with customers.

Many apps and software options can help businesses of all sizes and budgets. These include inventory optimization tools for keeping track of goods in real-time, and detailed reports that make tax time easier.

Inventory forecasting is very important for making sure that products are available. It also ensures that they are delivered on time and that the business grows in a way that lasts. By using these tactics, businesses can get supply and demand to balance out. It will greatly increase profits and customer satisfaction.

Conclusion

Incorporating fundamental strategies for inventory forecasting can significantly enhance operational efficiency while cutting expenses. It's vital to ensure that the appropriate inventory is available in the necessary locations.

Managing the computations for inventory forecasting using Excel and inputting the data by hand into your ERP system is feasible. However, maintaining precise records becomes nearly unfeasible when dealing with hundreds or even thousands of Stock Keeping Units (SKUs).

FAQs

1. Why is demand forecasting important for inventory management?

Demand forecasting is crucial because it helps businesses predict how much product they will need in the future. This planning prevents situations where a business might run out of products or have too much stock, both of which can be costly.

2. How does demand forecasting improve customer satisfaction?

By accurately predicting demand, businesses can ensure they have enough stock to fulfill orders promptly without overstocking. This reliability can lead to faster delivery times, fewer backorders, and overall better customer service.

3. What are the main components of effective inventory forecasting?

Effective inventory forecasting involves analyzing past sales data, monitoring inventory levels, coordinating with suppliers on delivery schedules, recognizing seasonal trends, and preparing for promotions or sales events.