Forecasting the Future: Supply Chain Management's Art of Demand Forecasting

In the complex world of supply chain management, demand forecasting is crucial. Demand forecasting for supply management is key for strategic planning. It supports companies in making data-driven choices. This method improves efficiency, customer happiness, and profits.

This blog will discuss demand forecasting in depth. We will focus on its role in improving supply chain operations. It impacts inventory control and production planning. It also boosts overall business flexibility. We will show its value in dealing with a changing market. Join us to learn about demand forecasting. It's essential for staying competitive in today's quick business world.

What is Demand Forecasting?

Demand forecasting is key in business operations. It predicts customer demand using past data and market trends. Advanced statistical tools help in this analysis. The process helps manage inventory, reducing overstock or shortages. It is crucial for setting production schedules in line with market needs, ensuring efficiency.

Demand forecasting in supply chain management guides strategic decisions. It supports developing strong business plans and allocating resources. The accuracy of forecasts affects a company's success. It helps meet customer needs, stay competitive, and grow sustainably. This forecasting is vital for a company's future.

The Importance in Supply Chain

Demand forecasting is crucial for supply chain efficiency. It helps companies avoid waste, cut costs, and balance supply and demand. Precise forecasts improve product availability. This boosts customer happiness. In a market with changing tastes and economic shifts, this is key. Here are five advantages of successful demand forecasting in supply chains:

● Better Inventory Management: Companies can predict future demand. This helps avoid overstocking and shortages.

● Cost Reduction: It streamlines buying and production, lowering holding and operating costs.

● Stronger Supplier Relationships: Accurate forecasts enhance teamwork. They make supply chains efficient and cost-saving.

● Superior Customer Service: Supply chains are managed for prompt product access. This ensures faster market reactions.

● Competitive Edge: Understanding customer needs enhances a company's market position. It effectively strengthens their competitive edge.

In short, effective demand forecasting is key for business longevity and success.

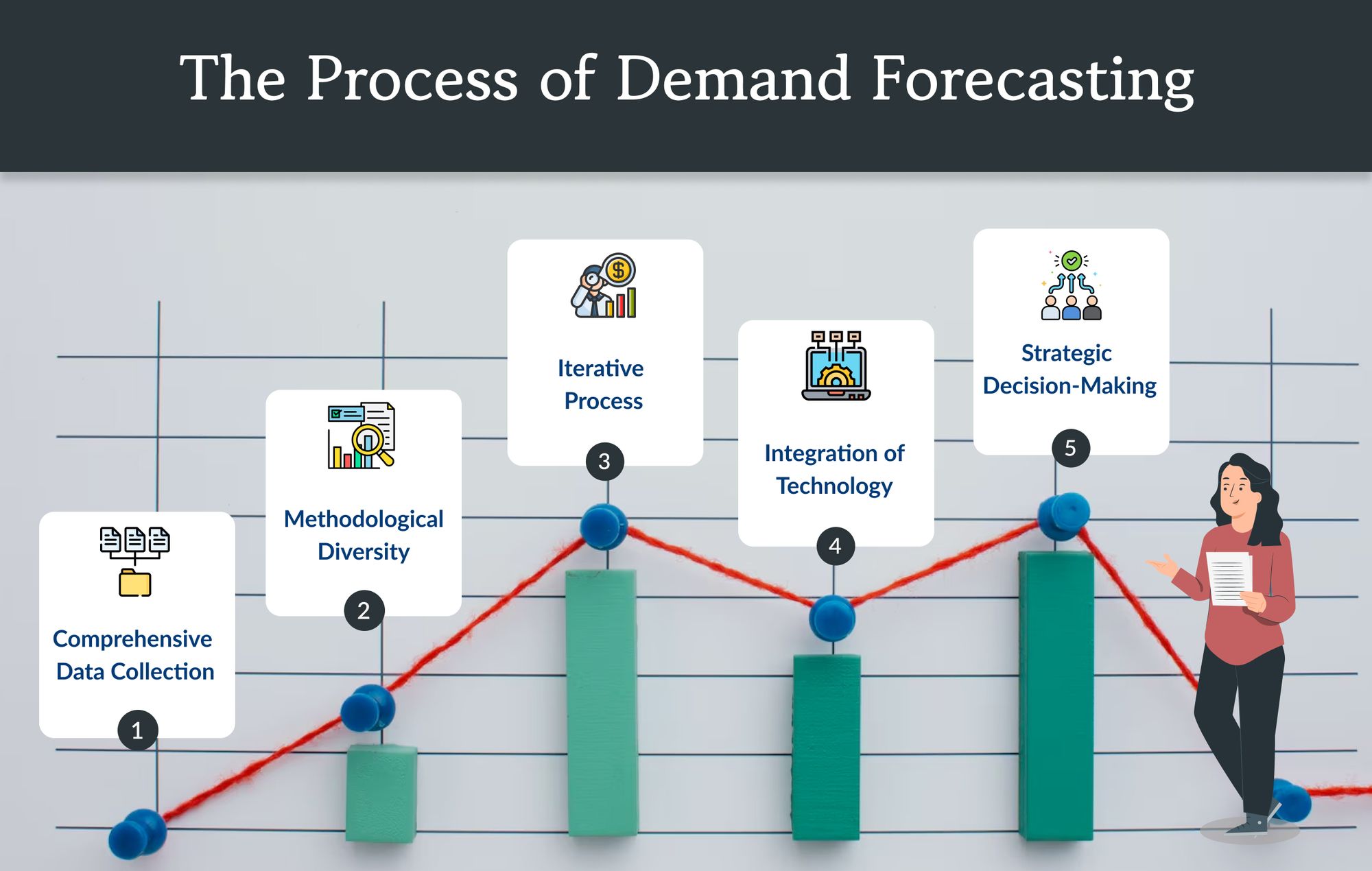

The Process of Demand Forecasting

1. Comprehensive Data Collection

Effective demand forecasting starts with detailed data collection. This process involves gathering various data types. Historical sales records and current market trends are included. Detailed consumer behavior analysis is crucial too. Economic indicators are also key. Both the accuracy and scope of this data are essential for reliable forecasts.

2. Methodological Diversity

The process uses multiple analytical methods. For understanding consumer feelings, detailed market research is essential. Quantitative methods are also important. These include time-series analysis and causal models. The choice of methods depends on data nature and complexity.

3. Iterative Process

Demand forecasting is ongoing and repetitive. It constantly adapts to market feedback and external changes. This continuous refinement ensures forecasts stay relevant and accurate.

4. Integration of Technology

Modern demand forecasting uses advanced technologies. AI and machine learning are particularly significant. These technologies efficiently process large data sets. They identify complex patterns and provide detailed, predictive insights.

5. Strategic Decision-Making

The main aim of demand forecasting is strategic planning. Accurate forecasts help businesses in several ways. They improve inventory management and align production with demand. Forecasts anticipate market shifts and help in resource allocation. This enhances operational efficiency and competitive positioning.

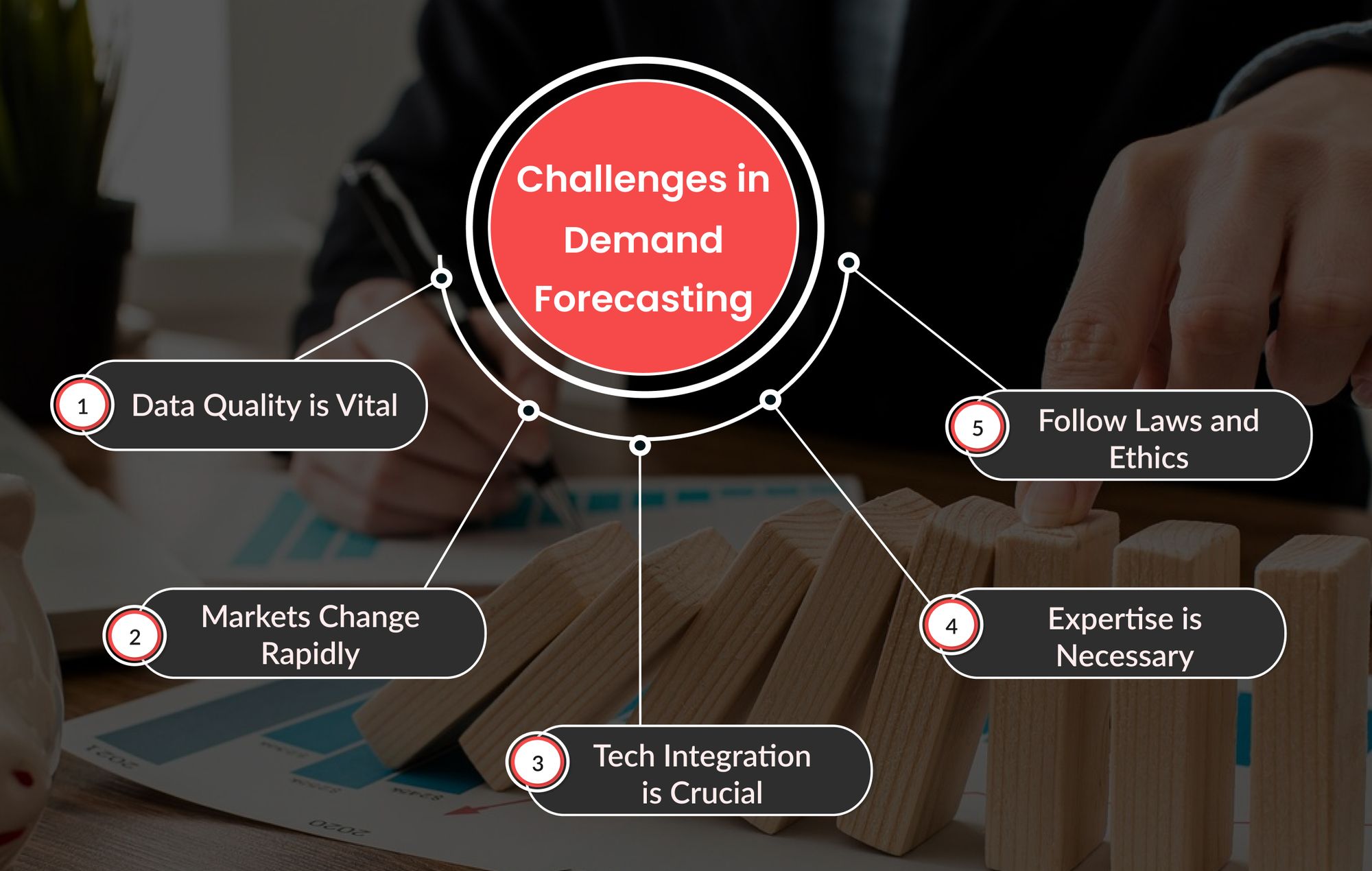

Challenges in Demand Forecasting

Predictive analytics depends heavily on data quality and timeliness. Poor or old data can cause wrong conclusions, affecting forecast accuracy. Key points to note are:

● Data Quality is Vital: Good, relevant, and current data is essential for accurate predictions. Poor data quality can halve model accuracy.

● Markets Change Rapidly: New competitors or economic shifts greatly affect forecasts. For example, tech market forecasts can vary by 30%.

● Tech Integration is Crucial: Using AI and ML can improve forecasts. But, this requires compatible systems and skilled use.

● Expertise is Necessary: Analyzing data and using advanced models need high skill. Without experts, data use is not optimal, impacting forecasts.

● Follow Laws and Ethics: Using personal data requires compliance with laws and ethical standards. Ignoring these can have legal and trust issues.

Forecasting success depends on reliable data. It also requires adaptability, technology, expertise, and ethics.

Best Practices in Demand Forecasting

1. Leveraging Technology

Using advanced technologies like AI and ML is key. They help forecast markets more accurately. AI and ML read big datasets and spot trends. They predict future patterns better than old methods. Predictive analytics uses past data to see future events. This gives businesses important insights for decisions.

2. Collaborative Planning

Involving many stakeholders is crucial. This includes suppliers, customers, and internal teams. It helps understand market trends better. Everyone's view improves forecast accuracy. This teamwork leads to stronger market predictions.

3. Regular Review and Adaptation

Markets always change. It's important to update forecasts often. They should match real-time data and feedback. This keeps forecasts relevant and right. Always checking and tweaking forecasts helps avoid mistakes.

4. Data-Driven Decision Making

Decisions should be based on data. This means using facts and numbers. It cuts down on guesswork. This leads to smarter, more effective choices.

5. Technology Integration

It's important to blend forecasting tech with business systems. This makes information flow smoothly. It ensures everyone has the latest, right forecasts. This coordinated approach improves the forecasting process.

How does the future of demand forecasting look like?

The fusion of Big Data and IoT is changing demand forecasting significantly. This synergy ensures unparalleled precision and speed through real-time data. A McKinsey report suggests it could cut forecasting errors by 20-50%.

Future forecasting emphasizes sustainability and ethics. Predicting demand for eco-friendly products needs insight into sustainable supply chains. It also requires alignment with global trends in responsible consumption.

Furthermore, tailoring and couture are assured trends. Market trends now focus on one preference. This shift requires updated demand forecasting for personalized choices. To meet these unique demands, supply chain processes must be optimized accordingly. According to a PwC study, Consumers are willing to pay more for experiences that are important to them: 43% of consumers would pay more for increased convenience, 42% would pay more for a warm, welcoming environment, and 65% of American consumers believe that a positive brand experience has a greater impact on consumer behavior than effective advertising.

In summary, Big Data and IoT are transforming demand forecasting. They promise better accuracy, ethical practices, and personalized experiences. In addition, continuity reviews are also influential.

Conclusion

Demand forecasting in supply chain management is crucial. It combines data analytics, market knowledge, and advanced technology. This area is key to enhancing supply chain efficiency. It helps businesses cut costs and improve customer satisfaction.

In today's digital world, accurate demand forecasting is crucial. It helps manage market and consumer shifts effectively. A Global Supply Chain Institute study reveals key advantages. Companies excelling in forecasting achieve up to 15% more inventory accuracy. They also see about 10% improvement in customer service. The use of AI and machine learning improves forecasting. These technologies offer more flexible and accurate models.

FAQ

What is the demand forecasting process in the supply chain?

Demand forecasting in the supply chain is a process that allows businesses to analyze customer demands according to market trends.

What is forecasting in supply chain management?

Forecasting in supply chain management involves the prediction of future demands for a product or service available in the market.

Why is supply chain forecasting important?

Supply chain forecasting is crucial since it enables businesses to carry out detailed analyses of different factors such as inventory management, production planning, and supply chain management.