Ways AI Can Benefit Demand Forecasting And Inventory Planning

Demand forecasting is the process of using historical data and other demand-driving variables to make predictions for better inventory planning and supply chain management.

It is an indelible part of supply chain management and operations planning as it allows supply chain managers to regulate inventory levels and production, and also prevent stockouts. Due to this fact, forecasting has been a part of supply chain management for decades now and has been a beneficial practice for businesses.

Recently, in the last few years, AI has seen a huge surge in multiple industries. Demand forecasting is a manual process that has also been automated by the use of AI and has revolutionized the operations planning and supply chain management process. AI has also nearly overcome the market unpredictability challenges due to Covid making it the next big thing in the demand forecasting and inventory planning space.

In this blog, we will elaborate on demand forecasting and the drawbacks of the traditional forecasting system. And then we will move on to discuss how AI can help overcome such drawbacks.

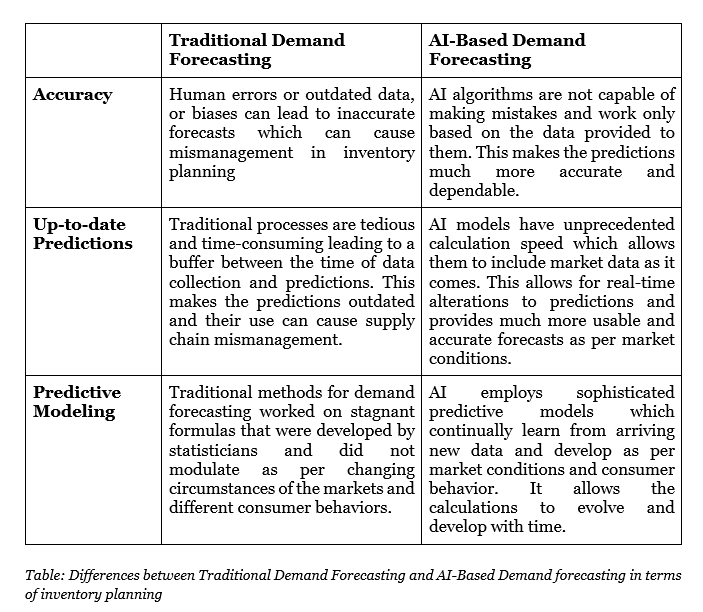

The Issue with Traditional Forecasting Methods

Traditional demand forecasting is a manual process that includes multiple spreadsheets. Unfortunately, ever since Covid hit, supply chain managers across the board have reported a supply chain disruption caused due to the rising volatility and unpredictability of consumer behavior.

As a consequence of this, all the historical data that was relied upon for predictions has become useless. Previously, seasonality patterns were regular, and the relevant historical data predicted the market trends accurately. But with the disruptions which seem to be permanent now, the nature of markets, as well as consumers, has changed.

AI in Demand Forecasting

AI has emerged as a very viable solution to the drawbacks faced by traditional forecasting methods. Firstly, AI brings in the advantage of automation which significantly reduces both time and resources spent on forecasting. Secondly, AI overcomes the unavailability of historical data by factoring in other relevant variables that may affect the demand data. This way, AI makes much more accurate predictions of market trends. Lastly, the data processing speed and capabilities of AI forecasting models are exceedingly greater than humans which makes the forecasting process much less tedious and the insights much more fresh and relevant.

Benefits of AI in Demand Forecasting and Inventory Planning

Automation of Processes

Demand forecasting is a manual process that traditionally takes a lot of time and resources due to it being a manual process. Supply chain managers use multiple spreadsheets and docs for the process which has been eradicated by the integration of AI. AI’s integration into forecasting automates this manual process making it much less of a hassle for managers.

Better Data Analytics and Pattern Recognition

AI algorithms are marginally better at data analysis and pattern recognition. Processing and considering huge data sets of historical sales, consumer behavior, market trends, etc. along with external factors as well, AI helps identify complex non-linear relationships between seemingly disconnected variables, providing much more accurate and informed predictions.

Predictive Modeling and Machine Learning

AI employs sophisticated predictive models that continually learn from new data. This iterative learning process enhances forecast accuracy over time, adapting to changing market conditions and improving the overall inventory planning process.

Enhanced Accuracy and Efficiency

Humans have the tendency to make errors and the process of calculation is also prone to low efficiency. Human calculations can also be biased a lot of times. To tackle this issue, AI demand forecasting automates the whole process making it streamlined.

By reducing human intervention and automating repetitive tasks, AI streamlines demand forecasting and inventory planning. The result is increased accuracy, faster decision-making, and improved operational efficiency.

Real-Time Demand Forecasting with AI

The processing of demand data is instantaneous in the case of AI-based demand forecasting. This allows for real-time predictions incorporating every new change in the market. Forecasts that are made considering all the fresh data and are developed in real-time are extremely accurate and the insights provided by it are marginally more actionable.

Conclusion

In conclusion, AI presents a revolutionary solution to the challenges faced by traditional demand forecasting methods in supply chain management. The disruptions caused by the Covid pandemic have rendered historical data unreliable, making accurate predictions difficult. However, AI's automation capabilities, combined with its ability to factor in relevant variables and process vast amounts of data, enable it to deliver highly accurate and informed forecasts. Moreover, AI's predictive modeling and machine learning continuously improve forecast accuracy over time, adapting to changing market conditions.

By streamlining the demand forecasting and inventory planning processes, AI brings increased efficiency, faster decision-making, and enhanced operational accuracy. Real-time demand forecasting with AI allows businesses to respond swiftly to market changes, ensuring better adaptability and agility in an ever-evolving landscape. Ultimately, embracing AI in demand forecasting empowers supply chain managers to optimize inventory levels, prevent stockouts, and drive overall business success through data-driven insights.